Our project Mondeo is treated to a block mod and a few other tweaks at BD Performance

Rep to race car project part 11 – in association with Teng Tools.

Regular readers will remember that in the last update we showed you the Mondeo Rep to Race Car was at BD Performance in Wrexham having a Helix Autosport clutch and flywheel upgrade. You can read the full update in the last issue, but the car is still at BD’s workshops – now it’s having a block mod, thorough health check, and a full alignment setup (after the subframe was dropped to remove the gearbox when fitting the clutch) so that it’s all ready for its next stop, which will be Collins Performance for a custom remap and dyno run.

With the clutch all back together and working as it should, the guys at BD Performance then turned their attention to the fable five-cylinder Duratec under the bonnet of our Mondeo. BD is a name synonymous with tuning these engines (we’ve featured plenty of Focus STs and RSs over the years that the company has had a hand in) so were at the top of our list when it came to working on our Mondeo.

Why? Not only do they have extensive knowledge of these engines, but BD is one of those companies that always go the extra mile to ensure the customer gets the best possible results. A classic case in point; when the guys removed the cam cover from our Mondeo they noticed that, like most of the engines, it was a bit grubby and the alloy had started to corrode. But before they reinstalled it, they degreased it, blasted off the corrosion, and even gave it a couple of coats of fresh silver paint.

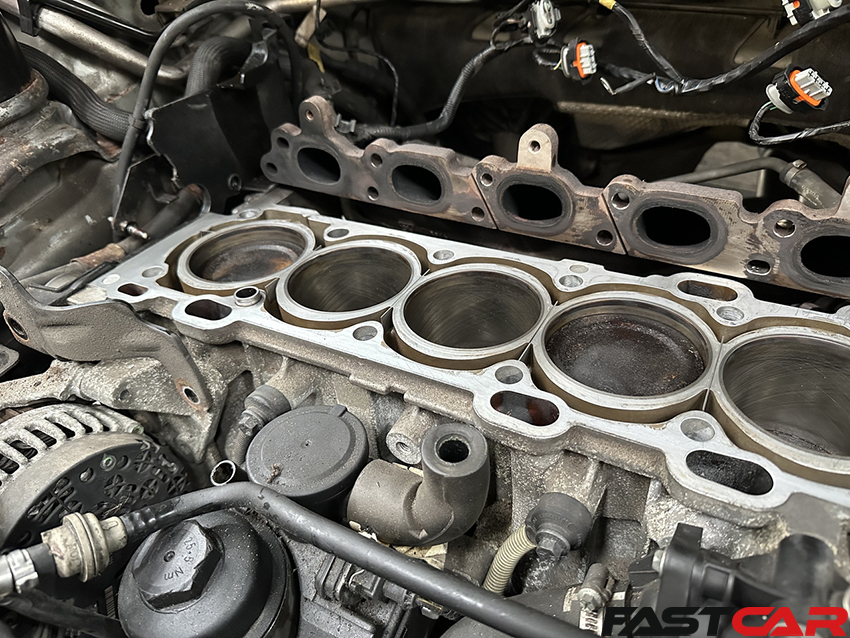

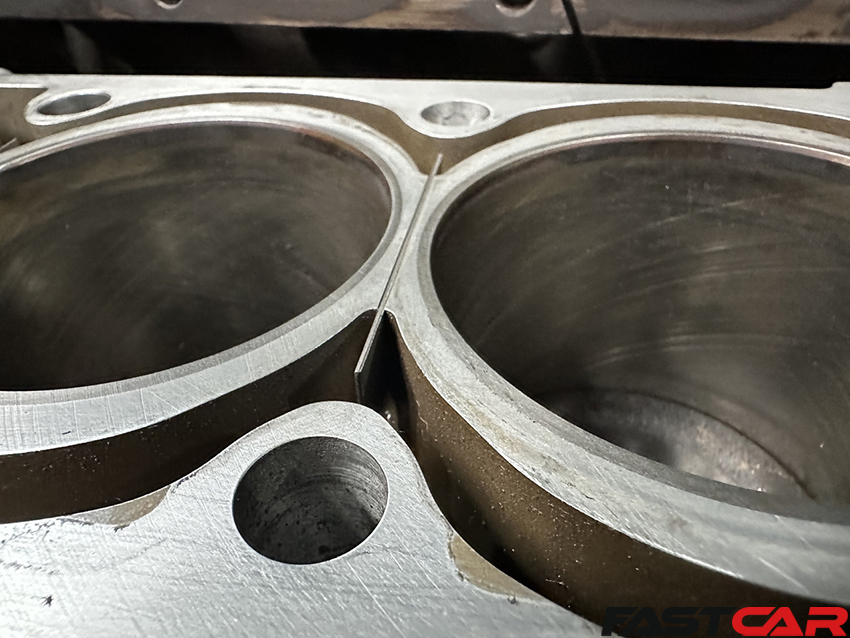

It was the same story when the cylinder head was removed to install the block mod. The head was a bit grubby – as you’d expect from an engine that’s covered over 100,000 miles – but rather than just wiping it down and whacking it back on, the guys at BD stripped it down and thoroughly de-greased everything. They even gave it a fresh skim just to be sure that it was all 100 per cent true. “Well, we’ve got the tools, so we might as well do the job properly,” smiles BD’s Darren Evans. And it’s exactly that ‘do it properly’ mentality that earns these guys their reputation as one of the best Ford tuners in the business.

It didn’t stop there, either. With the block mod installed and the engine cleaned up, the team fitted a new cambelt, and fresh gaskets, and did a full oil change at the same time.

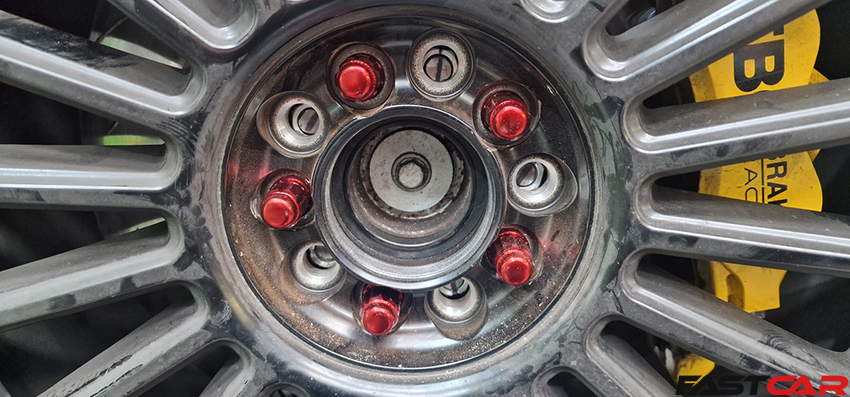

With the five-pot back together and running sweeter than it has in a long time, the team at BD then gave the rest of the car a thorough health check too. Knowing that the next stop is going to be Collins Performance and a lengthy stint on the dyno having custom software written, the BD team spotted and corrected a few niggly faults that needed rectifying. Thankfully they didn’t spot anything major, but tightening a leaky exhaust joint and fitting a new set of tuner-style wheel nuts were good spots that needed sorting.

The final job was to get the wheel alignment sorted. This is a job we’ve been waiting to do since fitting the coilovers, but we were waiting until after the clutch had been fitted as we know the subframe would need to be dropped as part of the process.

Now that it’s all back together again, BD suggested they would be able to get that sorted for us. Bonus, one less job for us when it comes back. We had an especially lucky escape when we learned that the rear toe adjusters were ceased and needed freeing off with the help of an induction heater to get them moving again.

But with everything loosened up and moving as it should, the four-wheel alignment was carried out and the Mondeo is one step closer to track action.

Next stop, Collins Performance. Come back next month to see how we get on, and how much power we can get out of this ol’ repmobile.

Rep to race car project part 10 – in association with Teng Tools.

Our Mondeo’s transformation from repmobile to race car is almost complete. The suspension, wheels, tyres and brakes have all been taken care of. And with the removal of the stock interior and fitting of bucket seats and race harnesses, the whole thing is starting to feel a lot racier to drive too.

That leaves one last major hurdle to overcome: power. We’ve got a plan in place and have already been speaking to Martin Collins at Collins Performance about writing some custom software to maximise the Mondeo’s potential, but there are a few things we need in place before the car goes anywhere near a dyno.

The first is an uprated clutch. The stock one was holding out but is bound to be on its last legs, having covered over 100,000 miles without being replaced. You can guarantee that the first time the car is strapped onto the dyno it would start slipping.

So, to lay the foundations for a solid base – plus allow a bit of headway for any further power increases in the future, because, well… race car – we started looking at options for a heavy-duty clutch upgrade. Because the car still needs to be driven on the road (remember, someone will win this car as a competition prize next year) we wanted to avoid unnecessarily hardcore paddle clutch options. But, we need something that will be capable of transmitting around 300bhp and 350lb.ft, and capable of withstanding the abuse that comes with track use too.

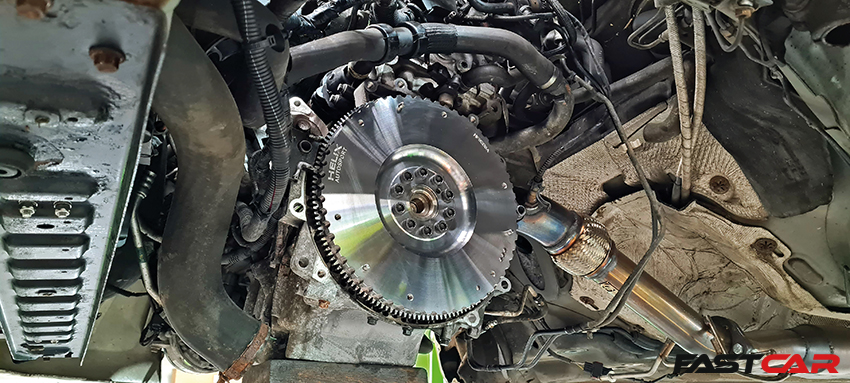

We got talking to the clutch experts at Helix back in the summer, and the company explained that one of its heavy-duty organic clutch and single-mass flywheel upgrades would do everything we wanted. Rated to over 400bhp and over 420lb.ft, the organic drive plate would be more than man enough to cope with the planned power increases, yet it is still compliant enough for daily use on the road. Perfect.

No wonder a full kit including a shiny new single-mass flywheel, uprated pressure plate and a new release bearing too was soon winging its way to Fast Ford HQ.

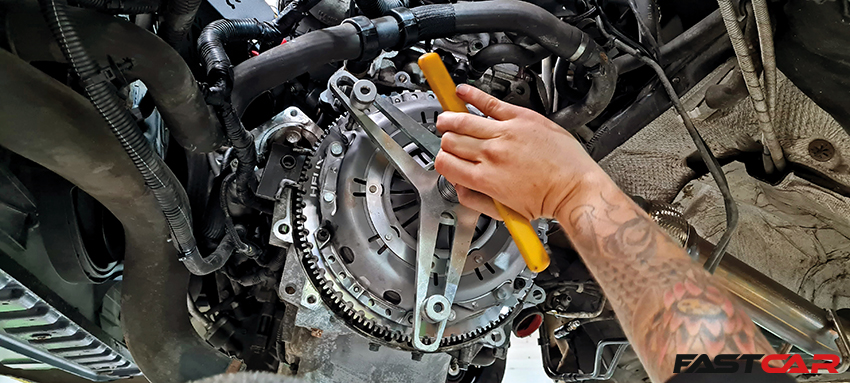

Then it was a case of getting it installed. It’s a big job, and best done by specialists who have all the tools (and knowledge) to do the job right. When it comes to working on these Duratec I-5 engines there’s one name that stands out above all others: BD Performance.

After a quick chat with Ben and Darren at BD, we were pleased to hear they were keen to get on board with the project. Ideas started flying around, and before long a plan was hatched. BD Performance would not only fit the new Helix clutch upgrade (the company is an authorised Helix dealer, after all, and has fitted loads of these in the past) but would also give the engine a thorough health check in preparation for remapping to come. They are even going to install the famous I5 block mod – not strictly necessary at circa 300bhp, but the added peace of mind is welcome ahead of thrashing it around the track.

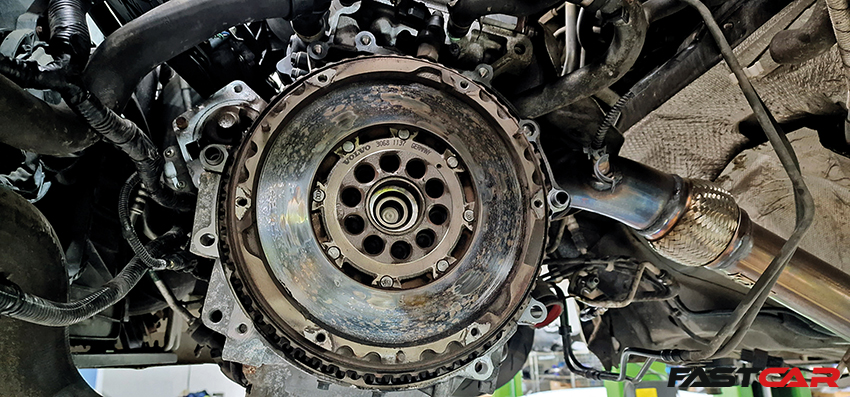

So, the car is now in Wrexham. BD Performance has completed the Helix clutch upgrade – as you can see from the photos – and is just about ready to start going over the engine for us too. We’ll have more on that next month…

Rep to race car project part 9 – in association with Teng Tools.

We can start this update with a brilliant bit of news: our Rep to Race Car project Mondeo could be yours. Yep, that’s right, we’re giving it away! Not just the car, but a load of tools and equipment from the project’s main sponsor Teng Tools too.

You will be able to enter our ‘Win A Car’ competition at the 2023 Kelsey events (JapFest, Ford Fair and TRAX), and this time next year you could be tanking around a racetrack in this unique Mondeo.

There’s a long way to go before then, though. The project is certainly taking shape, and with a host of performance and chassis upgrades, not to mention the race-style full wrap, it’s starting to look more race car than repmobile. Until you get inside, that is.

The Titanium X seats are undeniably comfortable, but even for spirited road use they do lack somewhat in the holding-you-in-place department. On track at maximum attack, you’re likely to be sliding across to sit on the passenger’s lap…

Our plan has always been to remove the standard interior and replace it with a pair of racy bucket seats with proper four-point harnesses. And while at Ford Fair a few weeks ago we got chatting to Corbeau’s Victor Lee about what seats would best suit our needs.

Vic noted some very valid pointers we should consider. The first tip was that reclining seats might be more practical than fixed-back buckets. As the car still needs to be driven on the road to and from tracks and will be driven by different people (remember, anyone can win this next year), having the ability to alter the driving position would be crucial. That also meant that we’d need to install sliding runners too, so we could adjust the position back and forth.

We then started chatting about harnesses, and while we wanted race-style four-point harnesses for track days, they can become a little restrictive for regular road use. Simple stuff like leaning forward to check you’re clear at a junction is made more difficult when you’re strapped tight against the seat. But Vic suggested that we could in fact run both types. Ideal.

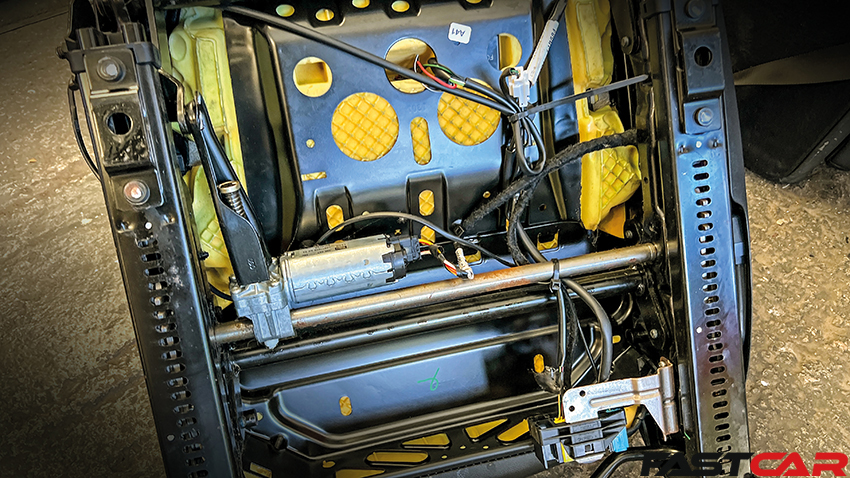

After trying our ample-sized rear ends in a selection of models Corbeau had on display at Ford Fair, we opted for the RS2 Reclining Seat. Available in black cloth with red micro suede inserts they certainly match the Teng Tools livery, and with supportive side bolsters they’re sure to hold even the largest of frames (like Jamie!) in place.

Installation was made much easier thanks to a pair of Corbeau’s model-specific subframes. No need to cut, drill, or weld anything: simply remove the original seats and bolt the Mk4 Mondeo-specific subframe into the same mounting points in the car. The sliding runners fit to the underside of the new seats and straight into the subframes, making the whole thing a bolt-in job. Perfect.

The harnesses were a bit trickier to install, and we were presented with several options: you can use the existing mounting points for the rear seats or use specific spreader plates and screw the eyelets into these.

In the end we used a combination of both to get the harnesses mounted securely and neatly. Removing the old seats did play havoc with the car’s airbag system, but that was nothing an evening on Google and a few cheap resistors ordered from the internet couldn’t fix.

The new Corbeau seats are significantly lighter than the originals too – which were packed full of unnecessary electric motors and heaters. Even the rear seats and seatbelt assemblies have some weight in them. Now that’s all gone, the Mondeo’s lost a few pounds as part of the process. Ideal for a track car.

But there wasn’t any time to sit down and enjoy the comfort of our new seats, as our appointment with BD Performance beckoned. Next up will be a block mod, health check, and installation of a nice new Helix clutch and flywheel upgrade that’s just arrived. Come back next issue to see how that all goes.

Rep to race car project part 8 – in association with Teng Tools.

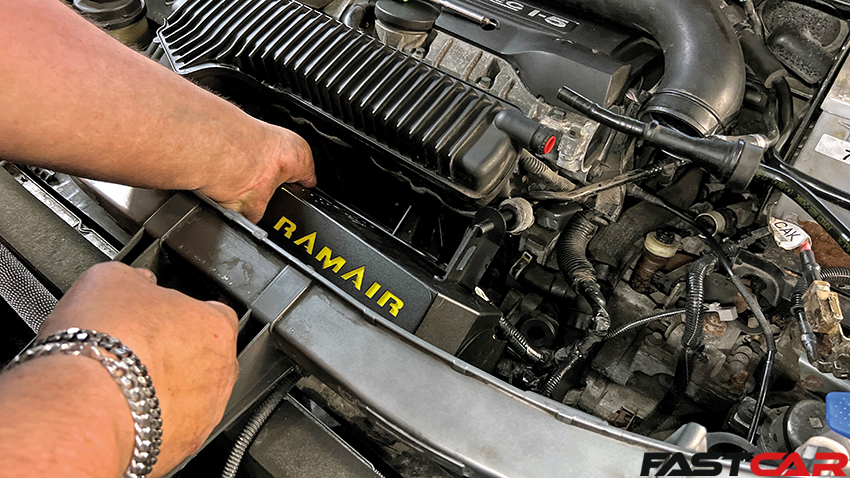

The Rep to Race Car project Mondeo gets an air filter upgrade with a complete Ramair induction kit.

The Rep to Race Car project Mondeo is starting to look the part, which means we now need to turn our attention to tuning its formidable five-cylinder engine.

The 2.5-litre turbo is very similar to that found in the Mk2 Focus ST – and, further tweaked, in the RS too – and is the main reason we chose the Mk4 Mondeo as a base for this project. But rather than a hot-headed tearaway like the Focus ST (famously nicknamed the ASBO), the stock Mondeo 2.5T is comparatively tame.

It will certainly get up to speed, and does so quickly for a car of this size, but it lacks the urgency of the ST. It was, after all, designed to waft along at motorway speeds in comfort, not attack the apexes of racetracks at full tilt.

But that’s all about to change. We’ve already been speaking to Collins Performance about getting the car on the firm’s high-tech dyno for a custom mapping session, and we’ve already started laying the foundations with some well-placed hardware upgrades such as a full Scorpion exhaust system and an Airtec intercooler.

The next thing on our list was the air filter. The stock unit is ugly and restrictive, so was promptly removed and binned. But, as with the Focus ST, the ECU attaches to the factory airbox; replacing the airbox means installing an ECU holder too.

Thankfully there are several options available, mainly because the hardware is shared with the Focus ST, and one of the best induction kits we’ve seen for the ST is the offering from Ramair. Comprising a proven foam air filter – that allows the engine to breathe much more freely and has been shown to work on big-power STs – plus a new aluminium ECU holder, the Ramair kit is a complete solution in one handy package.

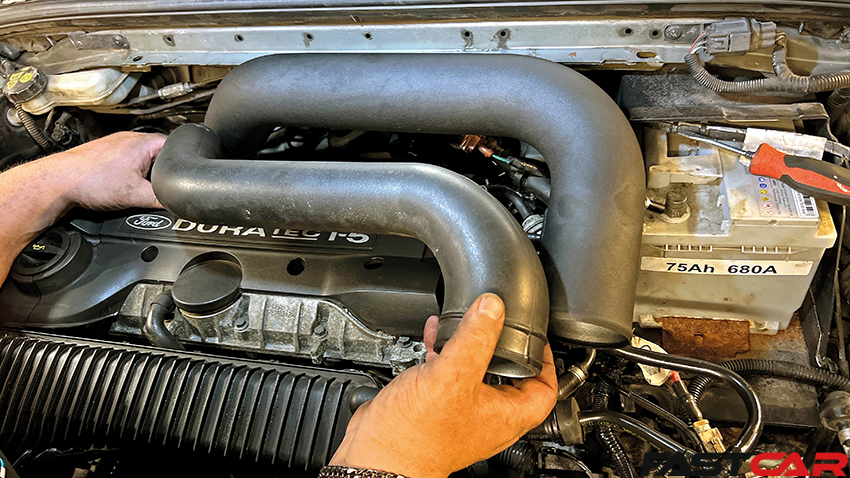

It all fitted together as easily as we’d expected and only took a few minutes to install. We could have just installed the induction kit and that would have provided more than enough airflow for the 300bhp-or-so that we’re aiming for. But as ST tuning has shown, further gains can be had by replacing the awkward-shaped standard plastic crossover pipe that feeds air to the turbo too. So, we ordered one of those from the Ramair website at the same time.

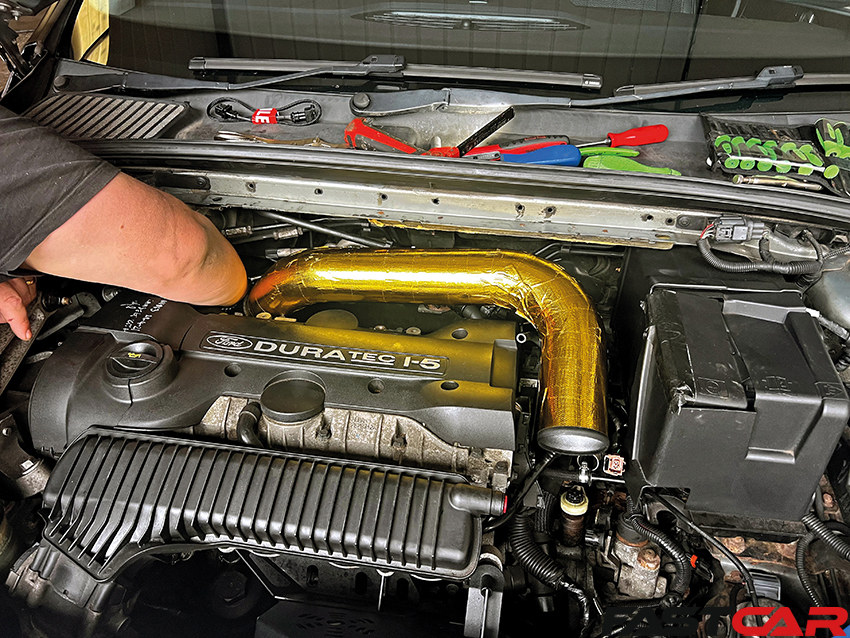

When it arrived, we wrapped it in some gold heat-reflective tape (badly; wrapping this stuff is a bit of an art form. Still… Race car…) and offered it up to the Mondeo’s engine bay. That’s when we noticed the odd vacuum pipe setup on the Mondeo. Further investigation revealed this to be the same style as fitted to the S-Max, Kuga, and a few Volvos. It’s an overly complicated system that uses a separate vacuum pump. And from our point of view, the excess pipework not only looked scruffy in the engine bay, it prevented the air filter from sitting where we wanted it. Also, the new Ramair crossover pipe only has provision for one vacuum fitting, whereas the original system uses two take-offs.

Clearly, some minor fettling would be required. We removed the heavy original vacuum pump and installed an RS-style pipe (complete with colour-coded braid) that simplifies the system; it now connects the inlet plenum and brake servo directly (through the OE one-way valve), much like you’ll find on a Mk2 Focus RS. The finishing touches were Ramair stickers.

Next up, the car is off to BD Performance to have a Helix uprated clutch and flywheel fitted, a block mod carried out, and one final health check of all vital components before it gets booked in for a custom mapping session.

ST-rivalling performance is now only a few weeks away…

Rep to race car project part 7 – in association with Teng Tools.

The Rep to Race Car project is taking shape quite nicely; we’ve still got a lengthy list of jobs to do and upgrades to fit, but if we stop to catch a breath for a second and look back, it’s already come a long way.

Upgrades to the wheels, tyres, suspension (coilovers), intercooler, exhaust system and a custom wrap have all been installed, and the transformation from repmobile to race car is well under way.

But there’s one area the stock Mondeo has been lacking in: brakes. The standard stoppers are reliable and quiet and do a surprisingly good job of hauling the old girl up from motorway speeds. But on track we’re hoping to be going a fair bit faster. And then having to slow down from those speeds several times per lap. Such repeated abuse would simply cook the stock stuff in seconds.

All good race and track cars need proper brakes; arguably more than they need additional power or any other upgrade. Therefore we wanted something that would offer some serious bite; more than anything the stock calliper would be capable of even with performance pads and discs, we wanted a bigger, more powerful complete brake kit.

But not many people list off-the-shelf big brake kits for the Mk4 Mondeo. Thankfully, our friends over at EBC aren’t afraid of a custom project car, so when we spoke to them asking how difficult it would be to make one of their big brake kits fit, they told us to drop the car off at their Northampton-based development centre and they would take a look for us.

So, just a week or so before Ford Fair, the Mondeo made a trip to Northampton, where the engineers at EBC got to work. EBC decided the most suitable kit for this car would be the high-performance four-piston calliper with braided lines coupled to a 355x32mm two-piece disc with BlueStuff pads.

This combo would offer a significant improvement in braking force and the ability to brake hard repeatedly without fade – a must for track cars. Also, as we still need to drive to and from the racetracks, this combo would remain fully road legal and compliant enough to use on the street, without fear of the brakes not working when not up to optimal temperatures.

Not only that, but when EBC put the whole kit on the scales we discovered that the new four-pot calliper setup was a whopping 3kg per side lighter than the old OE stuff. Keep in mind that’s unsprung weight, and in the case of the disc, rotating mass too – both of which have a huge impact on a car’s acceleration, braking and handling performance. Losing weight here has many benefits.

There is no kit available for the Mk4 Mondeo, but EBC does offer the callipers and component parts individually for one-off and custom jobs like this. Although, with more complete kits being added to the catalogue, most Ford owners can take advantage of EBC’s development and testing work, and just bolt the finished kit straight on. The Mk7/Mk8 Fiesta ST and Mk2 Focus RS kits are proving very popular now for that very reason.

With the car already in Northampton, and a tight deadline to get the car back on the road in time for Ford Fair, the nice chaps at EBC were able to hand us back the car at Silverstone. The Mondeo was proudly on display on the Fast Ford stand and was rightly attracting attention from show-goers throughout the day; the shiny new bright yellow EBC callipers peeking out from behind the spokes to catch your eye.

With the front brake kit installation only being completed a few days before the show, we ran out of time to replace the rear discs and pads with matching upgrades. EBC’s balanced brake kits include upgraded rear discs with the same slotted grooves to match the fronts, along with the same compound pad upgrades, but we’ll get those fitted at Fords Parts R Us by the time you read this.

That also means we haven’t yet had the chance to really put the new setup to the test. We’ll follow EBC’s guidance on bedding-in (which can be found on the firm’s website), and once that is complete, we’ll be able to offer a proper comparison.

While at Ford Fair, we also popped in to see Corbeau to pick the team’s brains about bucket seats and harnesses – Jamie even sat in a few to get a feel for which ones offer the best compromise of support and comfort, so expect an update soon. Oh, and while at Silverstone we also popped over to see Ramair to pick up a performance induction kit, spoke to Helix about a clutch and flywheel upgrade, and picked the brains of Martin at Collins Performance about custom remaps and how we can get close to 300bhp from the 2.5-litre engine too.

It was a productive day chatting to various specialists, but now we need to get back in the workshop and get to work once more.

Rep to race car project part 6 – in association with Teng Tools.

Things are progressing nicely with the Rep to Race Car project and the spec list is constantly growing, but there’s still a lot more we need to do before this car is fit for the racetrack. That’s what we’ve been looking at this month, and we’ve ticked off one of the first jobs on our list, which was an intercooler upgrade.

An intercooler’s job is simply to cool down the air that comes out of the hot turbocharger before it enters the engine. We need to do this because cooler air is more dense than hot air, and basically you get more bang for your buck with cooler air. While a performance-orientated intercooler will give power and torque increases over a stock replacement on a totally standard car, the main reason they are needed is to cope with the increased temperatures and airflow of a tuned engine.

In most cases, the factory intercooler just can’t cope; it can’t cool the air sufficiently, the temperatures increase, and – at best – the ECU pulls the power back to save itself from damage. Or, in the worst cases, things start to melt and get very expensive indeed.

Luckily for our Mondeo project, the specialists over at Airtec Motorsport offer an off-the-shelf intercooler upgrade even for our Mk4 TitX. These guys have the Ford market (and others) totally covered, and it made sense to opt for an upgrade that has already been tried-and-tested for installation and performance. Talking of which, Airtec says this upgrade will yield 5-to-15bhp increases on an otherwise standard car, and even bigger gains can be seen on tuned and remapped engines; something we have planned for the near future.

Looking at the diddy original intercooler compared to significantly larger Airtec upgrade, you can see why; it’s over twice as big. That means it has the extra capacity to cool more air, more efficiently – ideal for tuned engines where more air will need to flow through the intercooler faster to meet the engine demand.

But the size only tells half the story, as the whole intercooler has been designed to optimise airflow. Airtec’s new design features even higher-flowing end tanks feeding the 60mm intercooler core, which Airtec says has increased power and torque, and reduced temperatures at the same time.

As soon as ours arrived – complete with yellow Airtec logo to match the car’s livery – we called Mark at Ford Parts R Us and booked a day on the ramp. The Airtec kit comes with full fitting instructions, and while it is a bit of a squeeze getting such a large ’cooler in place, installation is all straightforward. The new unit bolts directly to the radiator crossmember, which does require removing and drilling for the new mounting bolts, but the hardest part was just removing all the OE plastic rubbish to make sure there is enough space for the new intercooler to fit.

Once it is all home, though, the intercooler bolts in place perfectly and even uses the original boost hoses, making installation simple and easy. And now we can benefit from cooler charge air temperatures – perfect, considering we fitted it in this summer’s searing 40C heat.

Behind the wheel, it does feel a little livelier but much bigger power gains will come with a custom remap, something we can look ahead to now we know the intercooler will cope. Before then we need to bin off the standard and restrictive airbox and fit a much freer-flowing intake system, and we’ve already been talking to EBC Racing brakes about building a set of custom stoppers for the project too. More to come next time.

Rep to race car project part 5 – in association with Teng Tools.

The transformation from repmobile to race car is really gathering pace, so after last month’s race-style wrap was applied to the Mondeo, this month we’ve turned our attention to the next round of mechanical upgrades.

We’ve still got a long list of performance hardware to install, but one thing that needed immediate consideration was the stock high-rise suspension.

Fair enough, the Mondeo was designed as a comfortable cruiser to waft along the motorway in a state of calm to de-stress pent-up businessmen as they road-trip between mundane meetings all day long. And it did that very well; indeed, it’s without doubt one of the comfiest cars we’ve ever driven.

But that doesn’t exactly lend itself to a sporty enthusiastic drive on the back roads or being hammered around a racetrack at full pelt. The standard setup is far too soft, and the ride height far too high for any spirited driving. If you did attempt to set a lap time anywhere, the only thing you’d achieve is making yourself feel sea-sick from all the rolling and wallowing about.

And then there’s the aesthetics too; the stock ride height is almost comical. The whole car needs dropping a couple of inches closer to the ground.

We needed something that would offer us some height adjustment as well as stiffer damping and firmer spring rates to help tackle the corners; we needed coilovers.

After some research it quickly became obvious that not many specialists produce quality coilovers for a Mk4 Mondeo – apparently, there’s not much call for turning the flagship repmobile into a dedicated track toy. Who’d have thought that?

But our searches soon saw us looking at the PB website. The company covers pretty much every model you could ever imagine, and not just the most popular ones. It even listed two different coilover kits for our CD345-chassis Mk4 Mondeo.

Having heard nothing but good reviews from readers who have installed the company’s big brake kits, and read a host of positive reviews online, we were intrigued to see what PB could bring to the Rep To Race Car project.

The PB kit we’ve chosen features monotube dampers with 30 damper settings and allows for ride-height adjustment between stock and -50mm lower. Reading the spec sheet reveals the units use high-quality NOK seals from Japan, superior damping oil from Italy, and the whole lot is covered by a one-year unlimited warranty. PB is clearly confident in the quality of its products, and after seeing and feeling them for ourselves we can see why.

But this project is not just about the driving experience on track; we still need to drive it to and from events and track days on the public roads, so anything that is too harsh would undermine the whole build.

Thankfully, the PB units come with 8kg/mm-rated springs, which offer significant handling improvements and drastically reduced body roll over of the stock setup but remain compliant enough to use on the public roads. And, thanks to the clever damper body design and shorter springs (180mm front, 225mm rear), adjusting the ride height doesn’t have any impact on the damping rates – even at the lowest setting.

As soon as the coilovers arrived we booked a date with Mark at Ford Parts R Us and wasted no time in getting them all bolted onto the car. We’re pleased to report no major dramas; other than the fair amount of surface rust and general road grime, the Mondeo’s mechanicals all seem to be in good health.

We wound the coilovers down to the lowest ride-height setting for ease of installation; the original plan was wind them back up again and roughly set the ride height with a tape measure ahead of a proper geometry setup later. But when Mark grabbed a wheel and bolted in back in place, we all stood back and thought ‘Hmm, that actually looks all right’.

So, with all four corners set as low as they would go, we dropped the car to the ground and rolled it off the ramp. It looks fantastic – much more ‘race car’ than ‘repmobile’.

But experience tells us that looking good and driving well don’t always go together, so we jumped into the car and went off for a quick blast up the road to test everything out.

It’s brilliant. Even at the drastically lowered ride height the car still feels smooth and compliant to drive; yes, you can feel it’s been firmed up, but it’s now more akin to a performance model than a race car that’s too harsh for the road – it’s still less choppy than Jamie’s Focus RS on standard dampers…

But when you get to some corners and start to throw it around it, you can really feel the difference. The front end has much sharper initial turn-in, and body roll has been significantly reduced too. Obviously, we didn’t get up to track-car speeds on the road test, but initial feedback is very positive.

For now, we’ve set the damper settings at level 15 all-round; smack in the middle of the 30-point adjustment on offer, to give us a sensible baseline to make small adjustments from. We’ll get some miles on the car to fully assess things, tweaking damper settings if necessary, and we’d like to get a full corner-weight setup completed before we venture out on track in anger.

But they’re best done a bit further down the line when we’ve finished with the upgrades; we’re hoping to strip a load of weight from the interior at some point…

In the meantime, the next thing to look at is making the car stop before we turn our attention to that five-pot and tickle some more power from it.

Rep to race car project part 4 – in association with Teng Tools.

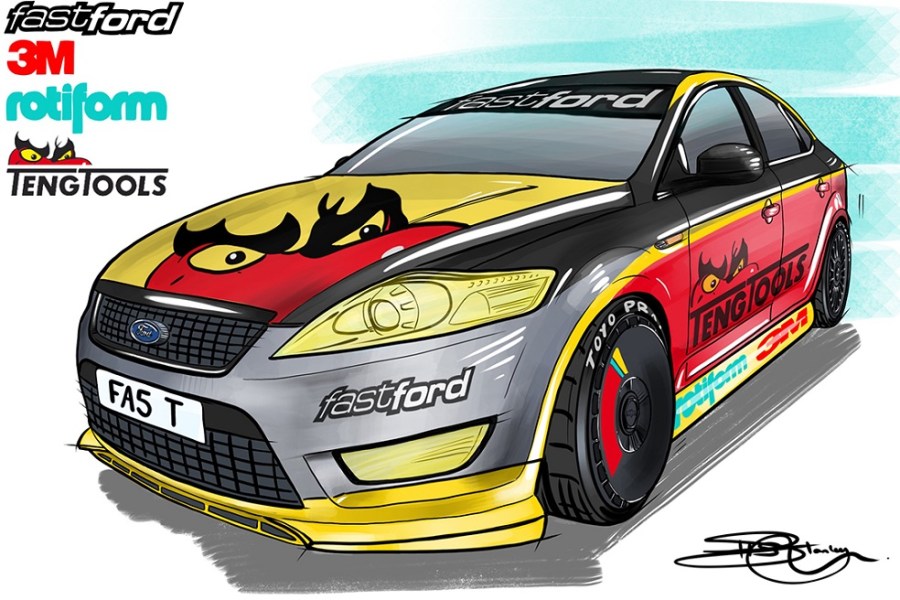

From the very start of this project, we knew that if we were going to pull off the rep-mobile to-race-car goal we would need a custom race-inspired livery to ensure it looked the part. That’s why we drafted in Helen Stanley for some custom artwork of how the project could look when finished. We showed Helen’s drawings to the guys at 3M Films, who said they could make the vision become reality. They suggested using their Approved Vehicle Wrapper (AVW), Popin Graphics in Cardiff, to apply the wrap.

Securing 3M’s coveted AVW status is no easy task, but when you look at the stunning facilities at Popin – not to mention the sheer talent of the people there – it’s easy to see why these guys are one of only a handful of companies to enjoy the 3M full seal of approval. With the artist’s drawings to use as a guide, the designers at Popin were able to get to work making a 2D plan for how the design would come to life on our Mondeo.

We were using the latest 3M films, which allowed us to combine several different elements into a single design to create a livery that really pops. With Teng Tools as the headline sponsor for the build, it was only natural that the colour-scheme would be red, black and yellow, but using 3M films we have been able to incorporate a satin black style for the roof and upper doors so that it doesn’t detract from the glossy red sides and rear bumper, and an incredibly bright yellow for the highlights that ties the whole lot together. Not only that, but because 3M films are fully printable, we have been able to use clever reflective film on the yellow areas.

This film has a reflective backing and is naturally silver in colour, but thanks to the latest technology you can print any colour (or design) directly onto the reflective films. A perfect example is the pair of eyes that forms part of the Teng Tools logo; the logo was printed on a single piece of (nonreflective) film, but we also had just the eyes printed onto a separate piece of reflective film too. Once overlaid, the Teng logo appears normal but now has reflective eyes that really glow when some light is directed at the car. The new design has made a huge and immediate difference to how the car looks. It certainly gets noticed, and the colour-scheme really stands out. It’s starting to look like a proper race car now.

As headline sponsors, the Teng Tools logo features throughout the design

One thing that race cars are covered with, are sponsors’ logos. Lots of logos. We’ve started adding our sponsor and partner logos to the Mondeo too: you’ll notice Rotiform, Toyo and Scorpion logos have already been fitted, along with 3M logos on the door mirrors, echoing the current upgrades.

As the build continues over the coming weeks, we’ll add logos for the products fitted and with plans for coilover suspension, big brakes, increased power and plenty more, we won’t be short of a logo or two. Next up will be fitting the adjustable suspension, but more on that next month.

It looks the part, now it needs the performance to match

Rep to race car project part 3 – in association with Teng Tools.

From Fast Ford magazine. Words: Jamie King. Photos: Jamie king and Jules Truss.

The Rep to Race Car build is in full swing, and things are coming along nicely. As you’ll have read last month the build process began with a thorough service and a shiny new turbo-back exhaust system from Scorpion. Some eagle-eyed readers may have spotted the Toyo R888R tyres in some of the photos, and yes, we fitted those at the same time, but we ran out of space to tell you all about them, so here they are looking damn fine in an update of their own.

The age-old saying of ‘wheels can make or break a car’ is still true, even on a build that’s destined for the track. Even more so, in many respects. Not only do we want a wheel that looks good, but we also need one that considers other performance factors: plenty of clearance for bigger brake callipers; better brake cooling; and lighter weight for reduced unsprung mass. And, of course, we want it to look the part too – especially when the car is on show in the Teng Tools garage at events like Ford Fair and TRAX. We needed a rim that offered performance and style and with that in mind, we jumped straight onto the Wheel Pros website where there are several awesome brands to choose from. Immediately our attention was drawn to the on-trend Rotiform page, where, after much deliberation, we finally settled on the multispoke BUC-M.

Toyo R888Rs of course…

Available in 8.5x19in with a 5×108 PCD and offset of ET45, fitment for the Mk4 Mondeo is perfect; the larger diameter fills the Mondeo’s enormous arches and allows loads of space for big brake kits to follow, and at 8.5in wide it means we can get a chunky 235-section tyre on there to give us plenty of grip too. Compared to the stock 8×18 alloys, these BUC-Ms allow us to go an inch bigger, half-an inch wider, and 10mm more aggressive on the offset – all while saving around 1.5kg per wheel for handling improvements.

Then there’s the style benefits: the BUC-M has a definite motorsport vibe to it – it even has the word ‘motorsport’ stamped into the rim – and will look right at home on our race car interpretation. The covered bolt holes give it a racy centre-lock feel too. We’ve also added a pair of Rotiform’s

Aerodiscs, which will get branded when the car goes for its full wrap.

Aerodiscs in steal mode

Of course, before we could fit the wheels, we needed to add some tyres, and when it comes to track cars the go-to option has long been Toyo’s R888R. As a fully road-legal semi-slick tyre it fits the bill perfectly; while we want to be able to do a few frantic laps in the Rep to Race Car Mondeo when it’s complete, the car also needs to be able to drive us to and from track days and shows without having to worry about swapping wheels and tyres to remain legal and safe for the road. Having previously used the R888R on several of our own project cars in the past, we know first-hand the performance benefits on offer – especially when warmed up on a track. Yes, they are a tad noisy compared to conventional tyres, but the days of this Mondeo being a comfortable cruiser are already long gone, and a bit of humming at motorway speeds is a price we’re happy to pay for the excellent levels of grip when it comes to track fun.

With the first upgrades in place, the build is set to continue at breakneck speeds over the coming weeks; we’ve got plans for a clutch and flywheel upgrade, followed by fully adjustable coilovers, and a big brake kit. Plus, at the time of writing this, the designers over at PopIn Graphics in Cardiff are busy working out how to make Helen Stanley’s artist impressions become a reality using the latest printable 3M films. Stay tuned for that update in the next couple of weeks.

The sun has set on this Mondeo’s days as a comfy cruiser

Rep to race car project part 2 – in association with Teng Tools.

Last month we introduced our new Rep To Race Car project; a somewhat crazy idea to see if we can turn a lazy but comfy rep-spec Mondeo Titanium into something that’s harder, sharper, faster, and capable of tearing up racetracks across the UK.

That’s not going to be an easy task and is going to require a lot of work to pull off, so this month we’ve wasted no time in getting stuck into the transformation.

We’ve already got support from Teng Tools – backing the project and providing the necessary sockets and spanners to complete such a build – plus Mark Sargeant at Ford Parts R Us, who will be skilfully wielding those spanners to make our vision become a reality.

But before we could get carried away with fitting all the performance upgrades, we needed to make sure the basics were all in place. The car has a full-service history and came with wads of receipts for previous work, so we thought we’d bagged ourselves a good’un. Yet there’s nothing like getting it up on a ramp and having a good old poke around for yourself.

Thankfully, despite the grime and dirt, everything looks solid. And evidence of the car being well cared for and regularly serviced was even more apparent when we removed the old air filter; it had clearly not been in for long. Still, we were covering all bases and ordered all the parts for a good service: oil filter, air filter, cabin filter and even two new auxiliary belts as the old ones had started squeaking on the alternator and power steering pump – not anymore.

We even treated the engine to a good flush out with Liqui Moly’s Motor Clean. This clever additive is designed to dissolve old oil deposits and nasty build-up from inside the engine – perfect for a 120k-miler that’s spent most of its life cruising up and down the motorways. Just add it to the oil, run the car at idle for ten minutes to let it do its thing, and then drain it all out with the old oil.

This left us with a nice clean engine, which we topped up with Ford-spec 0w40 oil. Then, to add future protection – and hopefully free up a bit more performance along the way – we topped the system up with Liqui Moly’s Ceratec additive. This is like a ceramic coating for the inside of your engine, reducing friction for added protection and improved performance too. Just the job for this Mondeo.

With the car fully serviced and given the thumbs up from our resident mechanic, we were given the green light to get stuck into the upgrades. First on our list, as with many modified cars, was the exhaust system. There were plenty of reasons for choosing to ditch the OE system: it’s a huge restriction when it comes to future tuning (especially the standard downpipe and catalytic converter); it sounded terrible – the five-cylinder five-pot should have a snarling off-beat growl, but the stock exhaust system muffled all of that; and finally, the original exhaust was rotten – one of the hanger brackets had already rusted away and broken off, and the rest of the system wasn’t far behind.

The perfect solution came in the shape of Scorpion Red Power’s stainless system for the Mk4 Mondeo. We’ve opted for the full turbo-back system, which means a high-flow 3in stainless steel downpipe coming straight off the back of the turbo. This will be needed later on when we start engine tuning work, and will allow the turbo to get rid of those exhaust gases much faster.

Coupled to the downpipe we’ve fitted a Scorpion sports cat. We could have opted for a de-cat pipe (which is significantly cheaper) but while the car is being built to take on racetracks, we still want to be able to drive there legally. A sports cat offers the best of both worlds.

Finally, the cat-back system bolts up to the sports cat and follows the original routing of the factory system, meaning it attached neatly to all the OE fixing points using the original rubbers. Our car did require some minor trimming to the rear bumper for tailpipe clearance – the system is designed to fit with the X Sport rear bumper, but we quite like the way it looks with the original Titanium X bumper. Plus, we may look to add a custom diffuser later in the build.

With the exhaust system fitted, we couldn’t wait to fire up the car to hear what it sounded like. What a difference! As soon as it bursts into life it has a much deeper growl and more meaningful burble at idle.

Give it a blip of throttle and it barks and howls like that much-loved five-pot should. After a run, and when everything’s nice and warm, you get a few spits and crackles on the overrun too – nothing like a pop-and-bang map, but some nice organic snaps and hisses that deliver plenty of audible encouragement.

Inside the cabin, it strikes the perfect balance of being sporty without being intrusive. It’s not at all offensive or too loud but has really beefed up the soundtrack to our car – perfect for our goal of being able to drive to a racetrack in relative comfort and then being able to set a blistering lap time.

It’s all moving the right direction, but we’ve still got a long way to go yet. As you can see from some of the photos this issue, we’ve recently taken delivery of some motorsport-inspired wheels and track day tyres – which we will cover in more details and show you being fitted in the next issue of Fast Ford – and then the car will be off for its race-style wrap shortly afterwards.

Rep to Race Car project part 1 – in association with Teng Tools

From Fast Ford magazine. Words: Jamie King. Photos: Jamie king and Jules Truss.

We’ve got ourselves a new project car here at Fast Car Entertainment HQ. And it’s not what you might expect. We feature loads of finely fettled fast cars –everything from old-school Escorts right through to the very latest hot hatches –but there’s one car that seems to be overlooked when it comes to tuning and modifying is the Mk4 Mondeo. ‘Why is that?’ we asked. Especially when the Mk4 is offered with the same fantastic five pot turbocharged Duratec that Mk2 Focus fans are so fond of in the ST and RS variants. And that got us thinking: can you take the humdrum motorway-mile-munching Mondeo and turn it into something ready to tear up the local racetrack? It’ll be no easy task, because the Mk4 Mondeo is a car firmly designed and developed to cruise the A-roads and motorways in comfort and control. So turning a soft, hefty cruiser into a sharp, precise track weapon is going to take a fair amount of work. But we’re not afraid of a bit of hard graft. And when we started looking into the prospect, we were pleased to see that, despite its relatively low production numbers, there’s still a wealth of tuning parts and performance upgrades available for the Mk4 Mondeo 2.5T. On top of that, UK tuning specialists boast one of the very best custom and one-off fabrication skill sets you’ll find anywhere, so if a particular part doesn’t already exist, we’re confident we can get it made for us.

So, to prove the point that you can take almost any standard car –no matter how unlikely –through a series of well-chosen upgrades from the right people, and then transform it into a genuine performance machine, our aptly-named Rep To Race project was born.

We spent the following weeks searching for a suitable car and our criteria were simple: it needed to have the 2.5T engine as shared with the sporty Focus models, and needed to be otherwise factory-standard. Surely that would yield loads of options, right? Wrong. The 2.5T is a remarkably rare car. And, on top of that, it seems to be increasingly popular too –we saw a few potential purchases that sold within just a day or two of being advertised.

Luckily, we managed to find what looks to be a bit of a hidden gem in this 2008 Titanium hatchback. It lacks the desirable X-Sport body kit that would have been the cherry on the cake, but it does come with a fully-stamped service history, and a folder full of receipts –including one for a recent cambelt and water pump change. That gives us a brilliant base on which to start the project. To give us some inspiration we even commissioned Helen Stanley from TV’s Goblin Works Garage and Motor Pickers to draw us an artist’s impression of the final build.

Fuelled with plenty of inspiration, we’ve been able to get the project up and running, and if you watch the video above, you’ll notice that the first mods have already made their way onto the car! They include a set of Rotiform BUC-M 19in alloys complete with a pair of Aerodiscs for the front, a set of track ready R888R tyres from Toyo, and a complete turbo-back exhaust system from Scorpion Red Power.

This is just the beginning, so make sure you keep up to date with the build in Fast Ford magazine, and right here on Fast Car but don’t forget to check out our social feeds on Facebook and Instagram for the very latest updates as they happen.