OBD2 is a familiar term in the modern car world, but what exactly is it? Hopefully all your questions will be answered in this guide.

Your car’s on-board diagnostics system is one of the most useful tools for not only diagnosing problems, but, if you have the equipment, you can live monitor or data log countless functions. In fact, you can even modify settings of both the engine and potentially, with the right equipment and know-how, every other electronically controlled part of your car. Such equipment can be found over in our guide to the best OBD2 scanners, but if you want to learn more about what they are, read on.

OBD2 stands for many things, from the connector plug design to the in-depth electronics, and this feature guides you through everything there is to know…

History of on-board diagnostics

Have a guess what came before OBD2? If you guessed OBD1, then you’re ‘sort of’ correct, but also not really. There’s officially no such thing as OBD1, which simply stands for any and all the on-board diagnostics setups that existed before the first ever standardized system was released, which is OBD2.

On-board diagnostics first appeared on some cars in the 1970s, and while incredibly rudimentary versus today’s stuff, and generally accessible by main dealer equipment only, it certainly existed on some cars for fault finding on fuel and ignition issues.

In the 1980s on-board diagnostics became far more commonplace, and while it was still relatively basic and still often main dealer orientated, some started having systems that allowed owners to read fault codes via a flashing light sequence shown on the dashboard or similar.

From the late 80s onwards, on-board diagnostics became much more sophisticated and relatable to what we see today, with some high end manufacturers having systems that not only diagnosed engine issues, but all of the cars electronics systems. The big difference to OBD2 was that things were not standardized, with every manufacturer having a different system that was totally incompatible with others.

Modern day diagnostics

On-board diagnostics standardization, aka OBD2, really came in to force in 1996, as from this point onwards OBD2 became mandatory on all cars sold in the USA. This, however, doesn’t mean OBD2 on late 90s vehicles are as sophisticated as current ones, far from it. It simply means the connection plug, generic functions, and basic software to connect to it are standardized. As the years pass, OBD2 functionality gets more and more sophisticated, and is likely to continue to do so for decades to come. However, while that’s great for diagnostic purposes, it does have some downsides – mostly in the context of car theft and security.

While OBD2 was mandatory in the USA from 1996, elsewhere in the world it took much longer; 2001 for petrol engine vehicles in the UK and Europe, 2004 for diesel vehicles in the same area, not until 2006 in Australia and New Zealand, and elsewhere in the world it was often much later. In fact, even to this day, many countries have no OBD2 requirement, meaning that while the majority of new vehicles have it fitted, it’s certainly still not all of them.

So what is OBD2?

To put it simply, it’s your cars electronic on-board diagnostics system, and it’s relatively standardized worldwide through all makes and models; in fact it’s the first and only standardized diagnostics system. It is mostly intended to check engine emission related issues, but has the potential to be a diagnostics system for a car’s entire electrical system, should the manufacturer wish to do so.

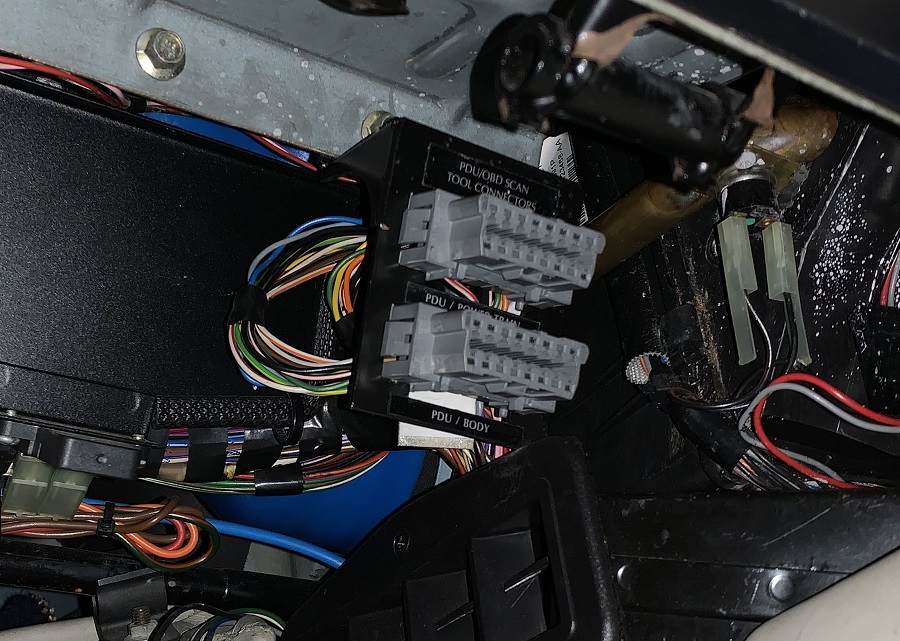

OBD2 has a standardized connector that most people simply call an OBD2 connector, but technically it is the J1962. It’s a 16 pin design, two rows of 8 pins, with angled ends to make it impossible to fit in the wrong orientation, and the female end being the one connected to the car. It can be found in various places depending on the vehicle, but rules state it has to be close to the driver, so it is usually under the steering wheel or in the center console.

While it’s a 16 pin design, only 9 of them have standardized functions, and the functions of the rest are down to the discretion of the manufacturer. Sometimes there is commonality between them, but generally that’s a coincidence as the pins are used for a huge variety of functions.

To access the OBD2 system you need some kind of scan tool with the appropriate connector and software. These can range from basic and cheap hand held devices that simply read fault codes and can perform a few other minor tasks, to professional level handheld diagnostics systems which can fault find and datalog all functions in huge detail, right up to laptop-based software that allows you to do all of the above as well as potentially modify settings throughout the system.

Understanding OBD2 fault codes

By far the most common use of OBD2 is, understandably, to diagnose faults on your car, and it displays this via fault codes.

Some diagnostic equipment will give you a detailed explanation of the fault as well as the code, but as more basic systems will simply give you a list of codes, you will have to then search for the meaning of these codes online. This is generally easy, though as some codes have more specific meanings on certain makes and models rather than the relatively vague meaning that code will have across all vehicles, it’s certainly worth seeing if you can find the info for your specific vehicle.

OBD2 fault codes are a letter and then 4 digits. The letter designates what area of the car the fault is related to, then the digits are the individual fault. The most common one you will see – in fact, many cheaper scanners will *only* show these – are the P codes. P stands for Powertrain, and basically means your engine, transmission, and related components. Aside from this, there are C for Chassis, B for body, and U for network.

Which problems fit under each code?

Chassis faults are things such as; ABS and traction control issues, air suspension, tire pressure monitoring, steering issues, battery issues, and much more.

Body faults are ones related to interior functions, wiper motors, central locking, electric windows and doors, and so on.

Finally, the network faults are related to the car’s overall data network, the wiring, sensors, and the various ECUs. If a component is not responding or communicating with the rest of the car, it will show here. This could be anything from audio system components to serious communication faults that will stop the car operating at all.

Numerical codes

Of the 4 digit codes, the first digit tells you if it’s a generic code that’s common throughout the car world or if it’s a manufacturer specific fault.

Most Powertrain ones you will see will begin with a 0, which means they are generic. This is because the main reason for OBD2 existing in the first place was for it to be a standardized emissions checking system, and generic powertrain codes do exactly that. Aside from these, P1 codes are manufacturer specific Powertrain codes, and P2 are generic but as of yet rarely if ever seen and are simply reserved for future use. P3, while also currently little used, is shared between generic and specific, with P30-P33 being manufacturer specific, and P34-39 being generic.

For Chassis, Body, and Network, the numbering system is much simpler, with C/B/N followed by a 0 or a 3 means generic, and a 1 or 2 means manufacturer specific.

Other OBD2 names

While OBD2 is a term generally understood worldwide and has the same functionality and fault codes regardless, it’s got various official names around the world, so it’s worth being familiar with these so you realize what they mean when you see it mentioned.

For example, in the UK and Europe the official name is EOBD, Japan is JOBD, and Australia is ADR79/01 and ADR79/02.

OBD2 tools

As mentioned, there’s various pieces of software and hardware that can be used to interface with your cars on-board diagnostic system, ranging wildly in price and functionality.

D.I.Y. tools

The most common is the handheld scanner. These are usually built to be strong and universal devices for home or workshop use, and can vary from basic systems that can simply read and erase most generic Powertrain fault codes, to professional level equipment with detailed live analysis and datalogging. Some potentially even have the ability to permanently change certain parameters within the car’s system.

Next up are wireless setups, which is usually a plug-in Bluetooth OBD2 adapter which you can link to specialist software on a phone, tablet, or laptop. Some highly sophisticated plug-in remote systems have GPS and WiFi, enabling the full diagnostics system potential to be done completely remotely if needed. Just like the handheld scanners, wireless setups can do anything from basic fault code reading to sophisticated logging of all sensors and data, to changing or remapping countless functions of the car.

PC-based OBD2 use is popularly used for more complex fault finding and modifications, and again can be anything from simple fault code reading to full custom remapping of the engine’s ECU and many other electronic functions of the car – if you’ve got the right software, knowledge, and skills, of course!

Many ECU re-flashing tools exist now which simply plug in to the OBD2 and allows the owner of the car to install a pre-made map they have purchased on to their cars ECU. These tools often also serve as a fault code reader and eraser too.

Insurance & emissions

The dreaded insurance company ‘black box’ is another item that’s often a datalogger and tracker fitted to the car’s OBD2 port. These take data such as acceleration and speed to determine if the driver is meeting their behavior requirements needed for their policy. While these items aren’t something anyone enjoys, fitting one can make insurance far more affordable for young drivers. Similar systems are sometimes fitted by companies to their cars to track workers and make sure they are behaving themselves behind the wheel!

In many states of the USA, as well as in certain other countries, emission testing is done via the OBD2 and the car’s inbuilt sensors, rather than the traditional tailpipe testing. Both testers and manufacturers can use the OBD2 to check for issues that can potentially fail any testing or even invalidate a warranty.

OBD2 uses for car mods

Last, but not least, due to the fact OBD2 can potentially tell you data from every single sensor on the car, it can be used to add supplementary gauges and display other data from your car via a fixed in-car electronic display. Countless versions of these exist, and you will find that some can display far more than others, and some will refresh the data far faster than others.

Either way, you can have a great looking and sophisticated data screen as part of your car’s dashboard, showing you every bit of data you will ever need, without the need for countless gauges cluttering up your car’s interior. All you have to do is plug the system in to your OBD2 port.