They look great, improve performance and sound awesome at full chat, but how do throttle bodies work? Find out the best car tuning tips and advice on throttle bodies with our guide to ITBs!

Throttle bodies are designed to improve the flow and increase the amount of air/fuel mixture entering the combustion chamber. The more air/fuel you can get in and out of an engine, and the quicker you can do this, the more power that engine will make. That’s the basics of all car tuning.

The engineering involved to produce a set of throttle bodies is immensely complicated. There are a number of factors that need to be taken into consideration to produce the perfect set of throttle bodies for a specific application. Whacking a set of motorbike bodies onto a huge, lazy V8 is never going to work. Neither is bolting a huge set onto a little, high-revving motor like the K20 from the Civic Type R.

To get a better understanding of exactly how throttle bodies work we took a trip to quiz the guys at Jenvey Dynamics.

What Are Throttle Bodies?

Before we delve into the complicated issues involved with throttle bodies, we need to know what one is and how it works. Most standard production cars come with a single throttle body. This controls the amount of air entering the engine. The butterfly opens and closes in correlation with the throttle position. Therefore allowing more or less air to enter the engine.

One single throttle body is adequate for the average road car. This is because it offers very gentle throttle response and is easily silenced to meet manufacturer’s noise limits. However, for a performance or fast road car you don’t want a gentle throttle response. Nor do you want to wait for the air to fill the entire induction system before it reaches the cylinder. You want instant throttle response. Therefore, the throttle butterfly needs to be closer to the inlet port in the head.

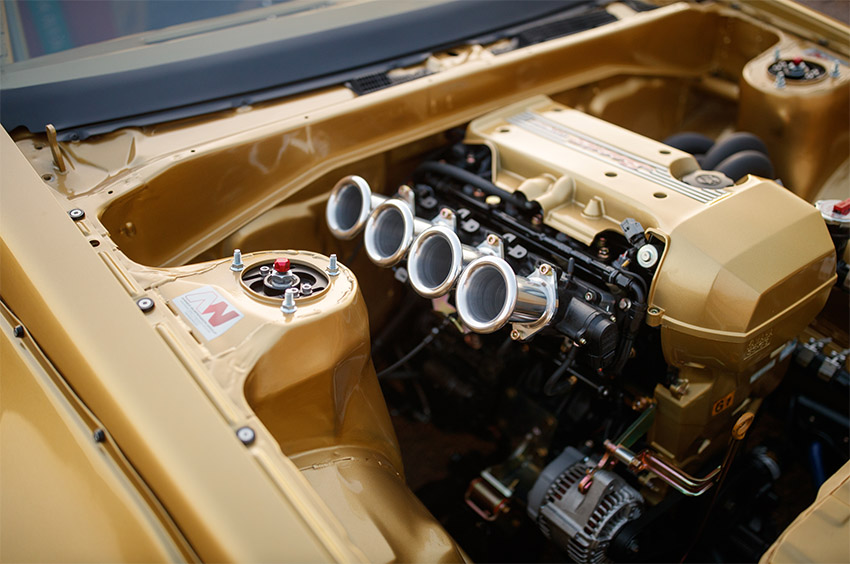

To achieve this, multiple throttle bodies are used. They work in the same way as one larger single throttle body. However, rather than the cylinders having to draw their air from one common source, each cylinder has its own smaller throttle body.

There are many advantages to fitting multiple throttle bodies. However, the main ones are improved throttle response and better mixture of air and fuel, which gives increased bhp and torque. Also the way multiple throttle bodies allow air to enter the cylinder at a higher speed allows the engine to rev harder.

What Are The Different Types Of Throttle Bodies?

Disregarding the single throttle body set-up, there are a number of ways multiple throttle bodies can be fitted. The straightforward solution for production engines is ‘twin bodies’. On a four-cylinder engine, this will be like older twin carburetor set-ups. It features two pairs of twin bodies. In most cases, the older-style carburetor manifolds can be retained, as the twin bodies will have the same bolt pattern. However, twin bodies can also be ‘direct-to-head’ fitment.

With direct-to-head bodies, no manifold is used. The end of the throttle body is machined to fit the inlet face of the head. The advantage is that the angle the throttle body sits against the head can be tailored to suit the angle of the inlet port. The more direct the airflow, the better the efficiency. On the other hand, a carburetor manifold has to sit at 90 degrees to the head. Machining the end of direct-to-head throttle bodies can be difficult. It’s hard to match the profile to those of the head’s inlet ports.

The best, no compromise solution is a set of single, individual bodies. Each cylinder has its own, standalone throttle body. A separate manifold is designed for use with the single bodies. This allows for greater accuracy in terms of port matching to the cylinder head and can be machined to best suit the angle of the inlet port. Single bodies can be tailored in size, shape and length to achieve the best mixture path for the application. Single bodies have the option of running multiple injectors per cylinder too.

Inlet Tract Length On Throttle Bodies

The length of the inlet tract plays a crucial part in throttle body design. When talking about the inlet tract we are referring to the distance between the inlet valve and the end of the trumpet.

Again this has an impact on air speed. According to Jenvey’s Simon Joyce: “The biggest cause of disappointment is with people who have an under-length system. This can result in a loss of up to a third of the power potential.”

The ideal length for a system will depend on other engine upgrades. Typically, a longer system will produce more torque and mid-range power. On the other hand, a shorter system will move the peak torque and power further up the rev range.

The available space in the engine bay will also play a part in the length of inlet tract used. In general, opt for the longest system you can get away with. To give you an example Simon explains:

“As a guide, if we had an inlet tract (center of valve head to face of trumpet) of 350mm, that would be the optimum for an engine revving to 9000rpm. It’s directly proportionate too. So, if we had an inlet tract of 175mm (half the distance) that would be ideal for an engine revving to 18,000rpm (twice the revs).”

The length of the inlet tract can be adjusted not only by the physical size of the throttle body itself, but also by using different length trumpets and manifolds. Also, if necessary, by the use of space plates too.

Taper/Parallel

There are two types of throttle body: tapered and parallel. Parallel are self-explanatory and both sides of the butterfly are the same size. Tapered bodies are tapered. The engine side of the body has a smaller diameter than the trumpet side.

This effectively turns the whole inlet system into one big inlet trumpet. The advantage is a constant increase in air speed. As the diameter gets smaller, the air needs to accelerate to get through it. This gives a smooth progressive acceleration of the air speed. Thus making it better suited for higher revving applications.

Throttle bodies – Trumpets

Also known as air horns, stacks or bellmouths, trumpets play an important role in how air enters the engine. They are the place where air from the surrounding atmosphere enters your car’s induction system.

There is a pressure difference between the induction system (which is under a vacuum caused by the intake stroke of the engine) and the surrounding atmosphere (which is at atmospheric pressure). Trumpets need to provide a smooth route for the air from the atmosphere to enter the induction system. And do so with as little energy loss as possible.

The way the trumpets taper from a larger diameter to a smaller one helps accelerate the air into the engine. It gives the required air speed, and provides a smooth progression to the next part of the induction system. This is usually the throttle body. The atmosphere end needs to be as large as possible to give the biggest area for air to enter the induction system. The narrower end needs to be exactly the same size as the throttle body to prevent any steps, causing turbulence and disruption to the airflow.

The trumpets complete the overall length of the induction system. These can be tailored to suit specific applications. As a rule, longer trumpets give increased torque and mid-range power, while shorter trumpets are better suited to higher revving engines.

Butterfly and Injector Positions

Position of the throttle butterfly and injector(s) in the inlet tract is vital to the way air and fuel is mixed. If either is positioned too close to the inlet port the distance for the air and fuel to mix is shortened. This isn’t so noticeable at low engine speeds. However, at high rpms the air and fuel don’t have time or space to mix properly to get the best performance.

You have to compromise because positioning the butterfly and injectors too far away from the inlet port will have a negative effect on throttle response. As with a single larger throttle body, the further away from the inlet port the more space the air/fuel mixture needs to fill before reaching the cylinder. The increased time this takes gives the delayed response.

Most production vehicles have injectors positioned as close to the inlet port as possible for good performance at low rpms, good economy and lower emissions. It also reduces the time available for the air/fuel to mix at high rpms.

With regards to the position of the injector in relation to the butterfly, Jenvey found that the optimum place is immediately after the butterfly (engine side). Simon explains: “Turbulence created as air passes the butterfly helps the air and recently injected fuel to mix and gives close to optimum results at both ends of the rev range. We recommend this for most applications.”

By moving the injector towards the end of the trumpet you give the air and fuel more time to mix. This gives results at high rpms. However, the pay off is drivability and throttle response at lower engine speeds.

Multiple injectors

You can run multiple injectors per throttle body. For most applications the two injectors will be in the same position. For some motorsport uses injectors are moved to each end of the inlet tract. By fitting one injector close to the inlet port and the other in the trumpet you can get a balance between lowdown throttle response and high rpm power. The injector closest to the port provides the almost instant throttle response. While the second in the trumpet allows the air and fuel sufficient time to mix to give optimum power at high rpms.

Throttle Bodies On Turbocharged Engines

Although usually associated with high-performance, naturally-aspirated engines, throttle bodies will also work equally well in forced induction engines. Obviously, they will need enclosing in a plenum chamber to hold the boost pressure. However, the same principals still apply.

Rather than relying on the pressure difference between the vacuum of the engine on the intake stroke and the surrounding air, the surrounding air is boosted at a greater pressure and is forced into the throttle body. From there on the principals are the same.

Diameter

Power, rpm, head design, cylinder capacity, the position of the throttle body in the inlet tract and the position of the injector all affect the size of the throttle body to be used. For example, fitting a set of motorbike throttle bodies, which are designed to work on a small capacity but very high-revving engine will not work if you then decide to bolt them onto a 5ltr V8 which will only rev to 6,000rpm.

The key behind a good set of throttle bodies is keeping the air speed correct for the application. Higher-revving, smaller-capacity engines will need a high air speed. However, not necessarily need to flow great volumes of air in order to fill the cylinders. Therefore, a smaller diameter body is needed to keep the air speed up. Conversely, on a larger-capacity, lower-revving engine the air speed won’t need to be so high. The more critical factor is filling the cylinders with air. This is achieved with a larger diameter body.

There’s a direct relationship between the diameter of the throttle body and air speed. Camshaft profiles and exhaust designs play a part. However, the basic relationship is the smaller the diameter the higher the air speed, but the less volume of air can pass through in a given time.

Performance tuned engines

However, in a performance tuned engine there will come a point when the physical size of the throttle body becomes the restriction to the airflow, regardless of air speed. As the engine’s power increases so will the amount of air it uses. At this point a throttle body which is too small will effectively choke the engine. Therefore, a larger one will be needed to allow the amount of air required through, while maintaining the same air speed.

As a guide, a 200bhp four-cylinder engine will warrant a 40mm set of throttle bodies. A 225bhp engine will use 42mm bodies. And to achieve 250bhp, you would increase the diameter to 45mm.

Barrel/Slider Throttles

These work on the same principal as butterfly throttle bodies, but don’t use a throttle butterfly. Instead either a roller barrel or slider mechanism is used to control the amount of air allowed to enter the engine.

Roller barrels are basically two tubes inside each other. The outer tube will have holes in either side (usually at 180 degrees apart), which allow air to enter and exit. The inner tube will have exactly the same holes machined in them. However, as it rotates inside, the outer tube will blank off the holes. With the throttle closed the inner tube will rotate right round so that the holes in the outer tube are completely blanked off. At full throttle it will rotate so that the holes in both the inner and outer tubes are lined up. This allows the air to pass through. Slider throttles use exactly the same method, but on a linear scale rather than a rotational one.

The main benefit of barrel and slider throttles is that at full throttle there is no obstruction to the airflow. With a butterfly, even at full throttle the air still has to maneuver around the butterfly itself, which causes some turbulence.

There are arguments for and against barrel/ slider throttles and throttle butterflies. The consensus is that barrel/sliders work better at full throttle. However, you have to compromise this against a loss of drivability and low down power.

There is another school of thought that suggests that the turbulence caused by the air passing a butterfly actually helps the air and fuel to mix better too.