We take a closer look at performance clutches, how they work, and why you might need one when tuning your engine; it’s our clutch guide!

The main purpose of an uprated clutch is to replace the standard item which can’t handle the level of torque the car is producing. It generally depends on the car and driver. A hard used, but less powerful engine will wear its clutch out far faster than a more powerful engine driven gently. Clutch wear can be as extreme as slipping instantly under load. Or it can occur when you use full power for short periods including drag racing, drifting, or during fast road use.

Standard clutches are designed so that even the least talented motorist can drive smoothly. But the payoff is a shorter life and inability to handle extra power. Many old school supercars for example, struggle to launch hard more than a few times without destroying the clutch for this exact reason. But if the manufacturer had installed a clutch that could effectively handle the power under hard use, it would be too difficult for most owners to use.

Read on through our clutch guide and you’ll become an expert in the field!

What is a car clutch and what does it do?

In simple terms, a clutch is the component that connects the engine to the transmission to drive the wheels. It works by using a friction disc (connected to the gearbox) pressed by a sprung pressure plate against a flywheel (connected to the engine) to transfer drive between the two. Disengaging the clutch – by pressing the clutch pedal – separates the friction discs and the flywheel. This breaks that connection between engine and gearbox. In turn, this allows you to change gear or stop altogether, with the engine running yet not providing drive at the wheels.

Are clutches all the same basic design?

Most automotive clutches use the same principle; some form of spinning friction disc clamped to a flywheel by a pressure plate to transfer power. But the types of friction materials used, the size and design of the discs themselves, and the number of friction discs used in any platform or application can vary.

The original clutch is adequate for a standard car. However, once you begin to increase power and torque, you will need a clutch with stronger pressure plate and more aggressive and hard-wearing friction materials.

What are clutches made of?

The outer pressure plates are generally a sprung-metal design, and the clutch friction discs themselves will use various friction materials depending on the application and power handling. The most common materials fall under the following:

Organic

Smooth, durable, usually quieter, and easier on the opposing mating surface. Organic materials are common but do suffer in very high-performance applications due to their intolerance to excessive heat and their shorter lifespan.

Carbon/Kevlar

Similar clamping properties to organic materials, with smooth operation but able to withstand increased heat much better when mated to a high-rated pressure plate.

Ceramic

Offering the highest friction co-efficient, the ceramic material itself provides more grip – which often means you don’t need such a high clamping force. The flip side is that ceramic materials wear the flywheel surface, sometimes causing shudder and a harsher feel. Mainly for competition use and applications where you are significantly increasing the stock power output.

How do aftermarket clutches differ to OEM ones?

OEM clutch kits work with the vehicle’s factory power output and most will begin to fail if you substantially increase that through tuning. Performance clutches (like those Helix produces) are available in different ratings to be able to work at much higher power and torque levels, meaning whatever your car’s power or driving style, there will be a clutch available to suit.

Also, many performance clutches are lighter than stock (especially when combined with a lightweight flywheel), meaning less rotational mass for the engine to turn, equating to freer revving and lower transmission losses.

Why, or when, would you need to upgrade your clutch?

It is worthwhile upgrading your clutch if you are planning a considerable increase in power and torque. For example, boost increases, re-mapping and engine builds will place more strain on the whole drivetrain and wear out a stock clutch more quickly. A performance clutch, on the other hand, is durable enough to cope.

The options available to you will depend on your level of power upgrade and intended usage.

How important is it to get the right clutch?

Aside from making sure you get a clutch that physically fits your transmission, you also need to consider your power and torque levels, plus your driving style and how you intend to use the car. There is no point simply buying the strongest clutch available if you are not going to have the power to warrant it, but under-specifying your clutch can lead to it wearing out prematurely and not being fit for purpose.

You’ll also need to keep in mind that pedal weight and ease of modulation are also a concern if you want to enjoy your car on the street, or want it to drive well and be useable in traffic –whereas for pure race applications an aggressive, snatchy clutch is less of a problem as long as it can take the constant abuse and hard-launch starts. The best thing to do is speak to a specialist like Helix Autosport.

What causes car clutches to fail?

Clutches are durable, but heavy abuse or increased power/torque will mean they wear much more quickly and need replacing more often. If the clutch slips, the friction disc could need replacing. You can tell if your clutch is slipping by flooring the throttle in a high gear at low engine revs and watching if the revs rise without a corresponding increase in speed. If this is the case, your clutch is on its way out. Clutches can wear out from repeated slipping such as stop-starting on inclines or from hard-launching the car with high revs.

What other mods should you consider when uprating your clutch?

You should consider upgrading the flywheel, and always replace the release bearing and flywheel bolts when installing a new clutch. Look for three or four piece kits that include a friction plate, cover assembly, release bearing and flywheel when applicable. This can save you money over buying the parts individually.

Are there any downsides to uprated clutches?

With single-disc clutches, driveability (especially in traffic) tends to suffer when you move to more aggressive designs such as paddle clutches This is because of their snatchy, all-or-nothing nature, which means useful clutch slip (to aid modulation when engaging) is pretty much non-existent.

The solution can be to use multiple friction plates. This increases the torque capacity of the overall clutch system but doesn’t necessarily have the snatchy bite and hard pedal feel associated with a traditional race-spec paddle clutch; this mainly occurs when your vehicle is running maximum power.

Multi-plate clutch upgrades are fast becoming more common for tuned road cars these days, because power levels can be incredibly high but owners still have a demand for usability on the road.

What makes up a clutch?

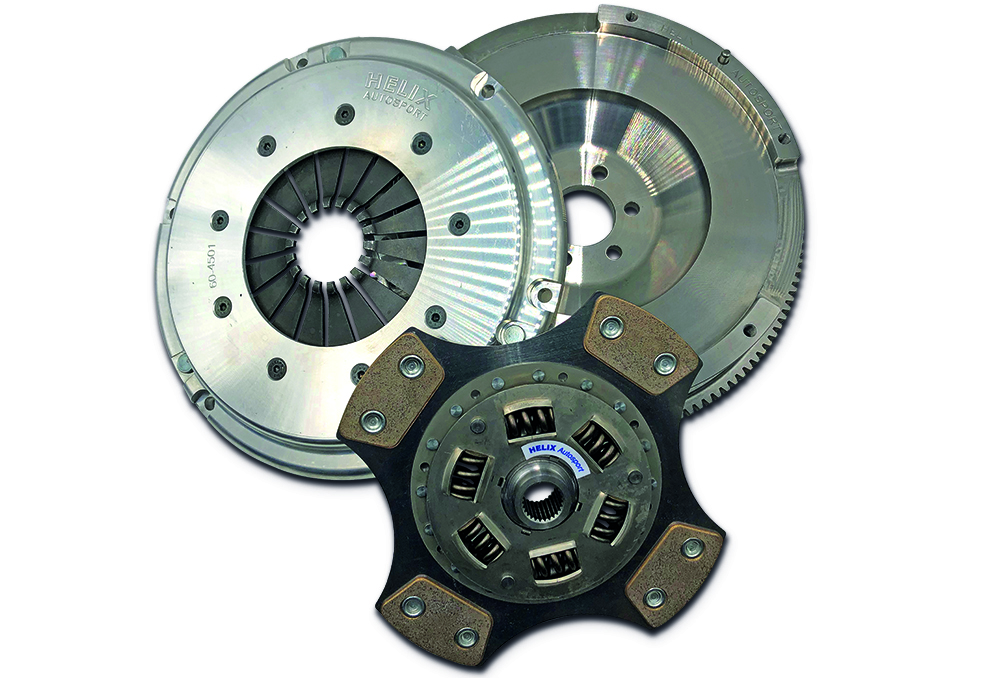

A clutch is fairly simple with three main components in a single plate example. It basically consists of two surfaces; one connected to the engine and one connected to the gearbox, and a central friction disc that transmits torque between the two.

Flywheel

This is the part that is bolted to the crankshaft of the engine and therefore spins at engine speed at all times. With the clutch engaged, the flywheel friction plate and the clutch plate press together, sending torque from the flywheel to the gearbox. Different weights of flywheel are available, and although these are mostly used for other performance reasons, a lighter flywheel will also have an increased clamping effect. We’ll explain the effects of flywheel weight later on in this feature.

Clutch plate

This is the part connected to the gearbox. When the clutch engages, the clutch plate is pushed against the flywheel to transmit power between them. There are various materials and styles of clutch plate friction pads depending on the use of the car and the torque the clutch is transmitting. More on that later in this guide.

Clutch cover

This is the part that pushes the clutch plate on to the flywheel when you engage the clutch. It has sprung metal fingers arranged in a circular fashion facing inwards that give the clamping force that helps stop the clutch plate and flywheel from slipping. An uprated clutch usually has an uprated cover which increases the clamping force of the clutch cover fingers. The downside of more clamping force is a stiffer clutch pedal, which can range from slightly stiffer to something barely useable on the road.

Paddle clutches

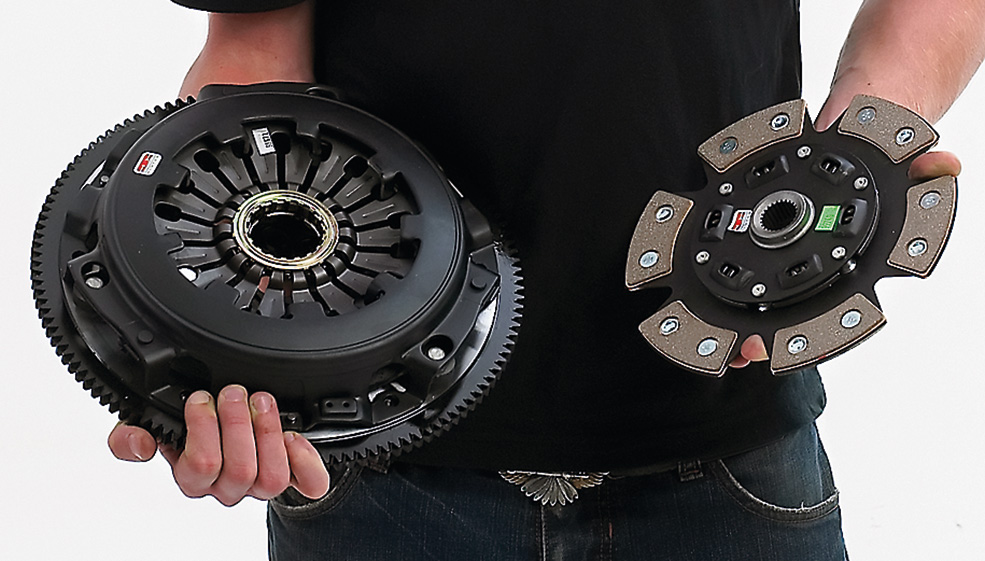

The majority of uprated clutches are known as a paddle clutch. A paddle clutch, rather than having 360 degrees of friction material like a standard clutch, segments into sections, usually four or six, but other combinations are available. These are commonly known as a four/six paddle clutch, or sometimes four/six puck in the USA. The reason for this segmented design is to help with heat dissipation. With increased power you are more likely to overheat the clutch, potentially warping it or simply ruining the friction material. Making it less effective.

Sprung plate or not?

Almost all uprated clutch plates for road cars, even ones intended for enormous power levels, are ‘sprung’. This means they have springs between the centre plate and the friction pads to dampen the shock load as the clutch engages. This makes driving it on the road, where the clutch is constantly being engaged and disengaged, much smoother than without springs. On race cars smooth clutch operation isn’t so important so these are generally unsprung to give the most positive action possible, less weight, and less potential failure points.

Multi-plate clutches

Multi-plate clutches are commonplace these days on tuned cars. They have more than one clutch plate with metal plates sandwiched between them. Using multiple plates spreads the load and increases heat dissipation, giving increased grip for the overall diameter of the clutch. This means a twin plate using friction materials that are more road-friendly can handle similar levels of torque to a single plate race-only sintered clutch for example. In race cars they use multi-plate clutches to save weight and rotating mass by using the smallest diameter clutch possible with a huge number of plates. Conversely, cars with very large diameter clutches as standard, V8s for example, tend to not need multi-plate clutches until a much higher power level than most four cylinder engines with smaller clutch diameters.

Flywheel weight

There’s a lot of talk about the effects of a lightweight flywheel, but to put it simply, on a high performance car there are many benefits. The first thing to remember is as it’s a rotating mass you are not simply removing 5kg. The effect is magnified by the speed of rotation and the gear ratios, meaning it can be the equivalent of a 150kg weight saving in a low gear, though in high gears it can be less than 10%. From a performance point of view it is why cars tend to rev faster and more freely with a lighter flywheel, especially in lower gears and of course out of gear. From a clutch point of view this lighter rotating mass makes it easier for the clutch plate to grip it, further increasing the clutches’ performance.

As ever with tuning, there is a downside, and that is a slight drop in drivability due to this decreased clutch mass as the revs drop more easily, making it harder to drive smoothly and easier to stall. Sometimes a slightly higher idle speed stops a car with a very light flywheel from stalling when the clutch is disengaged.

Hydraulic or cable operated clutch?

The vast majority of cars these days come with a hydraulically operated clutch. But there are still many popular cars with a cable clutch, Cosworths and Mk2 Golf GTIs for example, and this can cause problems when going for a high performance clutch. In a similar way to brakes without servo assistance need to pushing harder to operate, a clutch with cable operation is much harder to use than the equivalent clutch with hydraulic assistance. With organic clutches and standard covers it isn’t an issue, but once the cover is stiffer you need a strong leg to operate the clutch. Single plate clutches are just about driveable on a cable clutch, but anything more will need a hydraulic clutch conversion to maintain any hope of road drivability.

What are the most important things to look out for when buying an uprated clutch?

Look for a reputable brand or supplier. That way you know you will have great customer service and back-up should you have any problems.

You really do get what you pay for. That cheap alternative may end up costing you a lot more in the long run if it fails to live up to expectations.

It’s also worth considering professional installation. Not just because it’s a big job and requires lots of tools and equipment, but also because the alignment can be more difficult than you may think. The right tools really do make the world of difference when it comes to installation.