Discover the ins and outs of exhaust headers and their impact on engine performance. Learn about the different types of exhaust header designs and how factors like diameter, length, and volume can affect your car’s performance. Dive into the differences between 4-1 and 4-2-1 designs for optimum engine power.

Fitting a performance car exhaust is one of the most rewarding car modifications we can make to our cars. Unlike a cat-back or axel-back exhaust, the main job of a performance header is not to improve the sound of your car. Instead, its job is to help unlock power and torque increases.

But how does a simple metal pipe improve your car’s performance? Let’s dive into the intricacies of exhaust headers and explore their role in optimizing engine performance.

Exhaust Manifold Design

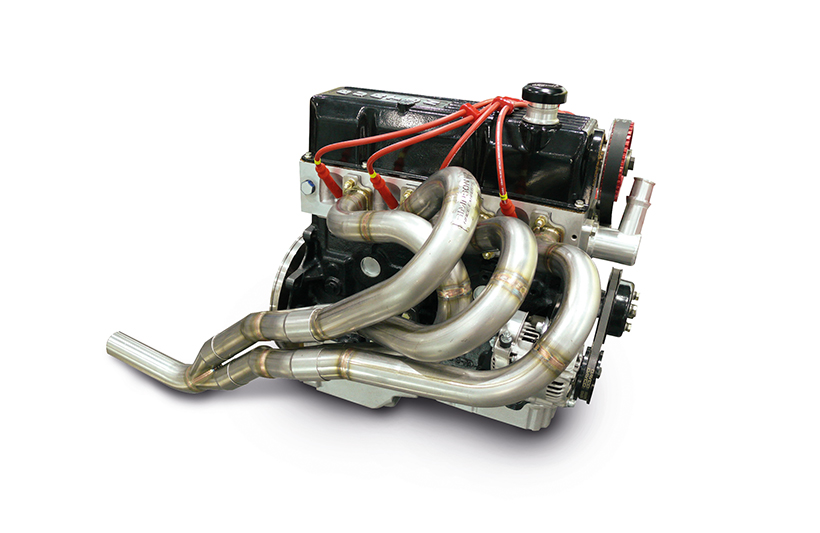

Standard production exhaust manifolds often fall short in terms of design and material quality. Most are made from heavy cast iron, featuring unequal length primaries and inconsistent bore sizes. Upgrading to performance headers is almost guaranteed to unlock increased power potential. For four-cylinder naturally aspirated engines, two main types of exhaust headers are available: the 4-2-1 and 4-1 designs.

The 4-2-1 Header: Maximizing Mid-Range Torque

A 4-2-1 header consists of four primaries linking into two secondaries, merging into a single collector just before the rest of the system. This design provides enhanced mid-range torque due to the vacuum created at the junctions where primaries and secondaries meet. The equal-length headers work in harmony with this vacuum effect, effectively expelling exhaust gases from paired cylinders. Typical pairings on 4-2-1 headers involve cylinders 1 and 4, and cylinders 2 and 3.

The 4-1 Exhaust Headers: Unleashing Top-End Power

On the other hand, 4-1 exhaust headers features four primaries that directly merge into a single collector. This design is preferred in applications where ultimate power in high rev ranges takes precedence over drivability and mid-range torque. Race cars that operate predominantly in the top end of the rev range benefit from the less restrictive nature of 4-1 headers. With its ability to expel exhaust gases quickly, the 4-1 design presents higher top-end power potential while sacrificing some mid-range torque.

Therefore, 4-2-1 headers are commonly used in fast road cars, whereas 4-1 headers suit high-revving race applications.

Header Bore Size

The diameter of the exhaust header significantly impacts performance. A smaller bore restricts top-end power but increases torque due to higher gas speed. Conversely, a larger bore reduces backpressure but allows for greater overall power.

The ideal bore size for your car will depend on a number of application-specific considerations. For example, 16-valve engines typically benefit from slightly smaller bores to maintain torque, while torquey engines can accommodate slightly larger bores for improved flow at higher engine speeds. Lightweight cars with lower torque requirements can utilize larger bore headers for enhanced top-end performance and power potential. Road cars generally favor slightly smaller bore headers, providing a wider torque spread, while race applications prioritize outright power through larger bore headers.

Header Length & Volume

The length of exhaust headers plays a crucial role in performance enhancement. More specifically, it’s the volume or equal length within the primaries that affects performance. Achieving equal volume in all primaries creates a “pulsing effect” as exhaust gases move through the manifold.

This pulsing effect, resulting from vacuum and pressure, assists in drawing exhaust gases from cylinders simultaneously. While achieving equal volumes in all primaries may be challenging due to design and manufacturing limitations, performance-focused aftermarket exhausts prioritize equal-volume primaries to achieve maximum gains.

Sports Catalytic Converter

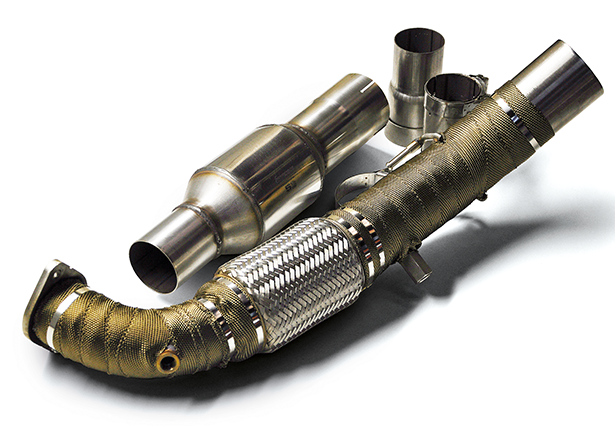

Post-1994 car models must comply with stricter emissions regulations, requiring the use of a catalytic converter within the exhaust system. Although catalytic converters reduce harmful emissions, they act as a significant restriction to exhaust flow, compromising performance. Completely removing the catalytic converter is not an ideal solution due to legal requirements. A sports cat presents a compromise between performance gains and emission reduction. Compared to the standard catalytic converter, sports cats have fewer cells per square inch, allowing for improved exhaust gas flow while complying with road legality and some race regulations. Cars produced before 1994 enjoy more relaxed emissions standards, eliminating the need for a catalytic converter.

Exhaust Headers and Manifold Coatings and Wrappings

Engine bays can get scorching hot, so minimizing heat is vital. Heat wrap and ceramic coatings act as thermal barriers, retaining heat within the exhaust system while keeping under-bonnet temperatures in check. Enhancing exhaust gas temperature maintains their energy and velocity, ultimately improving engine performance. Ceramic coating provides better durability, appearance, and tolerance to extreme temperatures compared to heat wrap, which offers similar benefits at a lower cost.

Transforming Your Car’s Performance with the Right Exhaust Headers

Upgrading your exhaust manifold is a pivotal step in optimizing engine performance. By understanding the impact of design, bore size, header length and volume, catalytic converters, and coatings or wrappings, you can tailor your exhaust system to suit your desired goals. Whether it’s increased mid-range torque or maximum top-end power, the right choices will unleash the true potential of your car’s engine.