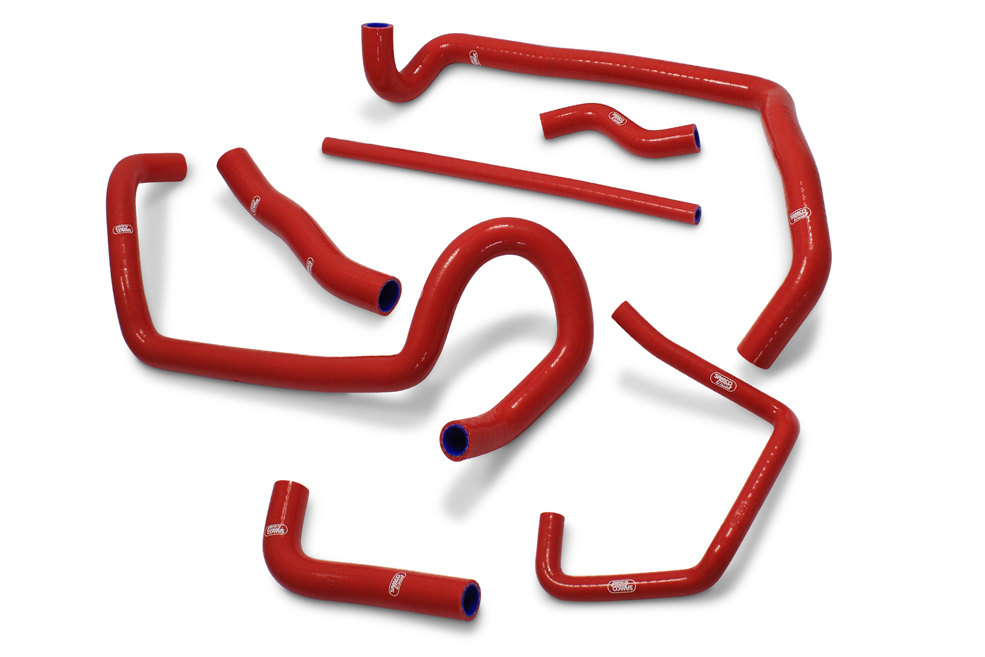

We take a dive into the world of silicone hoses, covering off what they are, why people upgrade to them when tuning and everything in-between.

What is a silicone hose and what does it do?

Silicone is an inorganic polymer consisting of carbon, hydrogen and oxygen. Silicone hoses are stronger and more reliable than traditional rubber-style hoses. They have several advantages over conventional rubber hoses, with their ability to run at much higher temperature ranges and pressures. They will also have a much longer lifespan thanks to them not hardening and cracking like rubber hoses.

Are all silicone hoses the same?

Not all silicone hoses are equal. Some hoses just offer a cosmetic finish to engine bays but can fail once put under higher-than-normal pressures. Fortunately, many of the bigger brands are tried, tested and trusted in the world of motorsport, with some even offering a lifetime guarantee. We’d recommend looking at SamcoSport or Forge Motorsport, two globally-renowned suppliers of silicone hoses.

Silicone hose construction

Performance silicone hoses are made from various layers of automotive silicones and fabrics, which manufacturers then compound to produce varying thicknesses of fabric-reinforced silicone sheet. They then use the sheet in the construction process of each hose.

Some hoses also add additional reinforcement (in big boost applications, for example) or add resistant liners for use with fuel or oil. On top of that, some also have fabrics designed to work with extreme temperatures.

How do aftermarket hoses differ from OEM hoses?

The majority of OEM hoses use EPDM rubber, which is cheaper and easier to produce than silicone but is also not as resilient to temperatures and pressures. A standard rubber hose has a maximum operating temperature of around 130C, whereas silicone hoses can cope up to 250C. The extra fabrics within the construction make silicone hoses less likely to split and fail under pressure too. Finally, many standard rubber hoses also include plastic joiners for ease of installation/manufacture, whereas many silicone hose upgrades remove these and make the hose in one piece for further improved performance and reliability.

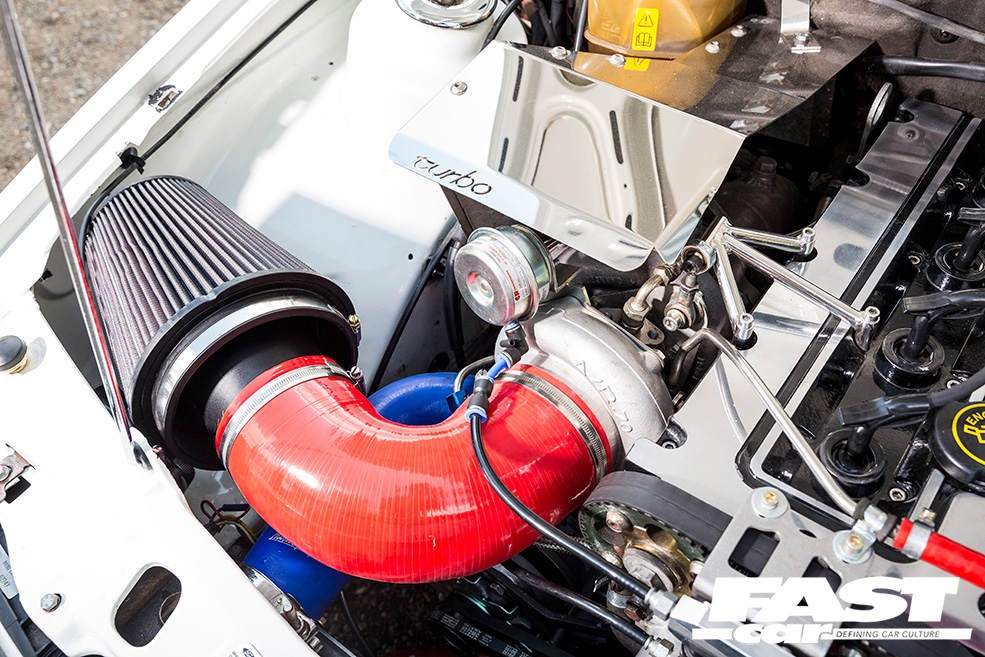

Why, or when, would you need to upgrade your hoses?

If you’re running a high-performance car, you should inspect OEM rubber hoses routinely due to the risks associated through heat cycling, cracking or even stress from increased boost pressure or increased coolant temperatures. If you remap the engine’s boost pressure by a large margin, then upgrading to silicone will certainly lower the chances of a potential catastrophic failure.

How important is it to get the right type of hoses?

It is very important to choose a good quality hose that has been engineered with the correct materials to enable it to deliver and exceed OEM requirements. If the hoses are not the correct diameter this can cause the hose to slip off the mating part when pressurized, or if too small can tear the fabric inside the hose, leading to a premature failure. It is also important that the hose is the correct shape to avoid contact with other components or moving parts.

What causes factory hoses to fail, or not be suitable for the task? Do aftermarket silicone hoses suffer the same fate?

One of the main causes of failure of factory hoses is oil degradation. Although silicone and rubber hoses are both prone to swelling when exposed to oil or oil mist from breather systems, Silicone has the better resistance to oil, and some silicone hoses come with a fluorosilicone inner liner to prevent the oil from affecting the core silicone of the hose. We also see factory hoses coming with plastic inserts or joints, which can easily crack and cause a failure. Age also causes OEM rubber hoses to fail: they harden and crack as the oils within the rubber dry out over time (in the same way rubber tires perish with age). Good quality silicone hoses won’t suffer from the same fate.

What other mods should you consider when uprating your hoses?

After extensive testing of clamps, some silicone hose manufacturers recommend using a marine-grade stainless steel hose clamp, which should have a smooth band with rounded edges and not have exposed drive slots.

Exposed-drive-slot clamps should always be avoided with silicone as they allow it to be squeezed through when the clamp is being tightened and then tear the outer layers of silicone and fabric, which can then lead to a premature failure of the hose and invalidate any warranty.

We also recommend that you use a good quality antifreeze, such as an ethylene glycol in a 50:50 mix with water.

Are there any downsides to uprated silicone hoses?

There are no downsides to using uprated hose apart from making your mind up on the vast range of colors available. The only other issue we can think of is the skinned knuckles you’ll inevitably get when working in your engine bay…