This modified 1968 Nova is nothing like Chevrolet first intended with a whole host of custom mods and a widebody finish like no other!

The 1968 Chevrolet product line for high-performance buyers featured Corvettes and Camaros and with powerplants that included 327s (Camaro), 350s, 396 and 427 powerplants. Power and performance, that was the scene with the “muscle car” era running at full peak speed! This story story isn’t about the ‘Vette and the Camaro, but rather revolving around the “little brother” Nova, the small Chevy that perhaps didn’t get the same amount of attention, however it could be a real performance contender as well when equipped with a hi-performance engine.

1968 Chevrolet Nova history

A little history of these third-generation cars, all-new body in 1968, with the styling continuing unit the end of the 1972 model year (the ’73-’74 cars received big, massive, front and rear bumpers). Novas rode on a wheelbase of 111-inches, with this new body redesign incorporated smooth, rounded lines. The “Chevy II Nova” (no longer with Chevy II markings after 1968) now featuring a semi-fastback roof design and only 2- and 4-door sedans were available.

Small-block V8s could be had in 307, 327 and 350 cubic inch sizes. New to the line in ’68 was the fitting of a big-block (396-cid) V8 engine in “Super Sport” trim. This top performer was the L78 version, rated at 375 horsepower. Featuring 11.0:1 compression, rectangular ports, solid-lifter camshaft, Holley 780-cfm four-barrel on aluminum intake. The 12-bolt rear axle could receive optional 4.73, 4.10, 4.56 and 4.88 axle ratios, automatic and 4-speed transmission choices. If one knew about this option, it was a true “sleeper” as compared to the flashier Corvettes and Camaros, a serious and potent performer!

Of all these of this generation the ’68 was most unique as it still incorporated the “old school” ignition key in dash design (others were anti-lock column mounted) and that feature gives it a real feel of a vintage ride from the ’60s.

Original modifications on the 1968 Chevrolet Nova

The back story of this feature car is that it belonged to a customer of JBA Speed Shop, San Diego, CA, and it had received a number of high-performance modifications and enhancements. Included in the work was a complete from subframe replacement kit, tubular A-arm front suspension, front coil-over adjustable shocks and rack and pinion steering upgrade. On the rear, a complete “FAB9” rear axle assembly from Chassis works was fitted, along with an adjustable sway bar and adjustable coil-over shocks. The brakes were updated with Wilwood discs front and rear.

Engine mods

Under the hood was a big block Chevrolet of 454 cubic inches, and the induction system came from Vortech, a complete supercharger system (centrifugal design) that included a V-7 YSi turbine with 3.33-inch 10-rib pulley, supported by a beefy 1/2-inch billet aluminum mounting plate. A Holley HP EFI Multi-Port system (rated at 1000 cfm capacity) supplies the fuel, mounted atop a Holley single plane aluminum intake. A pair of aluminum Edelbrock heads were included in the build, and internally the powerplant is equipped with 9:1 forged pistons and Comp Cams Hydraulic Roller Cam (.520/.539 lift, 288/294 duration) Spark provided by an HEI distributor and exhaust by Doug’s Headers. A potent and reliable engine that also has major league eye appeal!

Power is put to the tarmac via a reworked 700R4 4-speed automatic, routed to the 9-inch rear end (Ford type) that has 3.25:1 gearing, ideal for street cruising. This car handles stops and performs with impressive results, and with all that, the owner next got the urge to give the stock body some more flash, and that would include some seriously enlarged wheel openings that would house some sticky, new, wider 20-inch rolling stock With the rumble of that supercharged big block, and the huge rolling stock, the custom one-of-a-kind Nova is everything but inconspicuous everywhere it goes!

A Restomod that the owner wanted more

How did this body upgrade come about?

The car owner had surfed the Internet and came across an automotive “keyboard designer” named Rostislav Prokop, who hails from the Czech Republic, and this dude goes to the extreme in dreaming up wild creations! A black 1969 Nova was one of his video presentations, complete with music, and it was a real eye-opener for the customer to visualize that his Nova could be the recipient of such a wild and radical “wide body” conversion! And when he approached JBA Speed Shop about doing this type of “surgery” on the car, they looked over the video, made some photo copies detailing the concept, and agreed to do it right their in their shop!

Of course designing a car with a keyboard and mouse is a different assignment than actually doing a rear car, and the staff at JBA was able to determine the car on the video had some unrealistic features (such as 30-inch wheels and a channeled body section) and advised the customer that in order to get the work done and actually be able to drive the car in and out of driveways, be able to steer the wheels lock to lock and have clearance for suspension travel, well, it’s not going to exactly have the appearance as seen on the computer screen, but will certainly incorporate the general flavor of the rendering. And in the end, JBA Speed Shop was able to turn “pixels” into sheet metal “reality” and it is a true one-off design.

JBA Speed Shop does it all!

Who did the actual custom fabrication and design work on the wide body conversion? Inside the walls of JBA is a special metal fabrication team of Dallas and Jesse Patterson, and this father-and-son duo do magic with sheet metal and conceptual automotive design! Dallas’ experience work in the art of car design includes being a clay stylist at the famous Chrysler Pacifica Advanced Design Studios, and son Jesse has been doing metal work and related since the age of 13! Talent overflow with these craftsmen!

What’s unique about this JBA Speed Shop is it’s really a one-stop shop of all things high-performance, along with custom car-building capability! Sure they sell headers and manifolds, superchargers, EFI upgrades, camshafts, all that. Oh and they also build complete pan to carburetor (or supercharged!) engines, and test them on the dyno. Yes they have two chassis dynos for tuning and evaluating cars and trucks (even off-road race trucks!) as well as mounting tires, selling tires and wheels, hi-speed spin balancing, four-wheel alignments, yikes, just about every thing under the sun, and including restorations of classic cars. Add in the ability to create, as example, this one-of-a-kind widebody Chevrolet Nova, well you’ve got a place that seemingly does it all!

One would have to go back to the era of the Barris shop, Larry and Mike Alexander (Detroit), Bill Cushenberry, Deal Jeffries, Darryl Starbird, those pioneers and others that did magical work with metal in creating customs and show cars back in the day. But the neat thing is, JBA Speed Shop can still do it today.

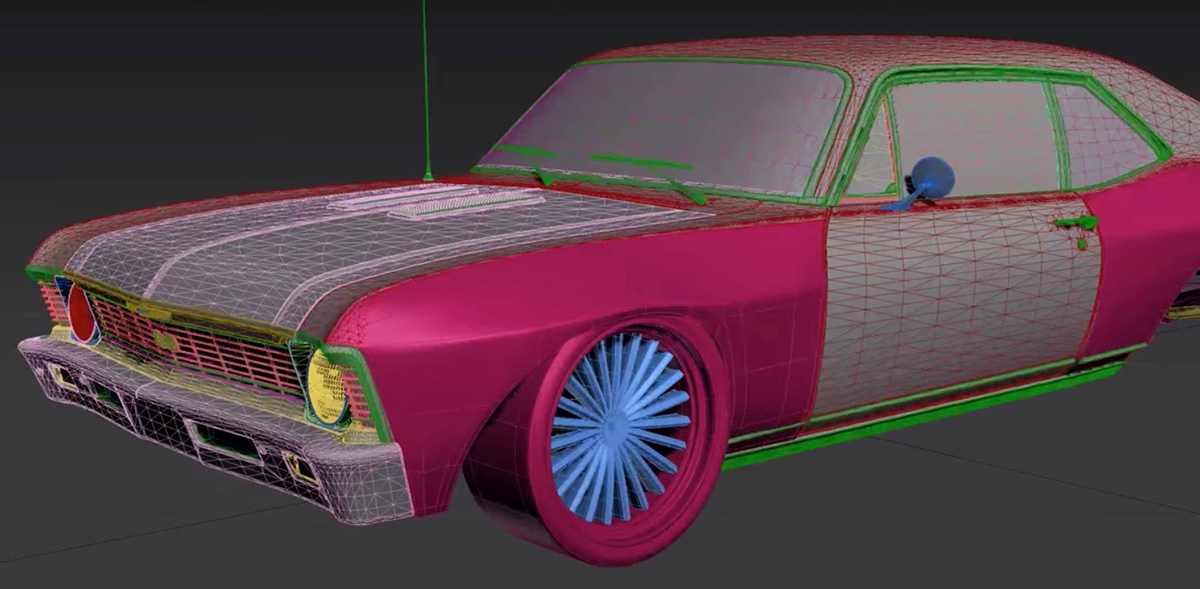

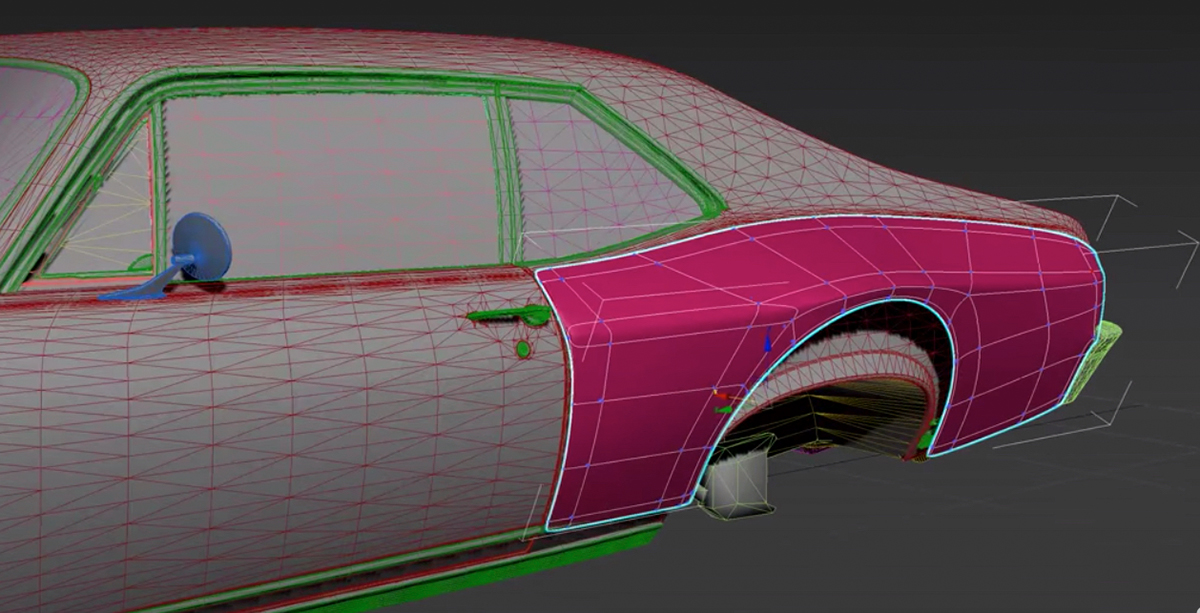

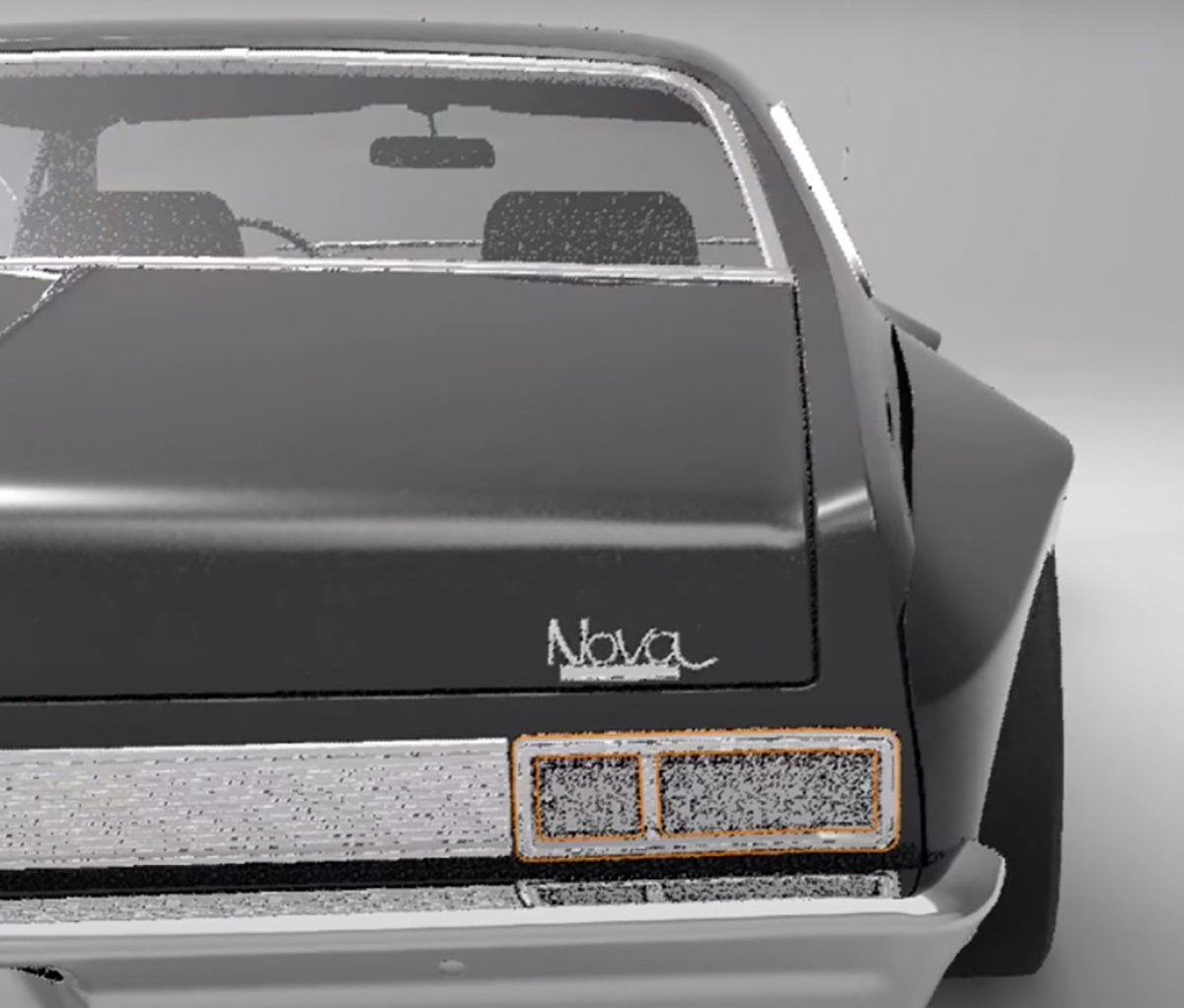

Internet Artwork

With a large fan base in Instagram, Facebook and YouTube, “Rostislav Prokop” is an Czech automotive designer / graphic visualization artist that does up concept cars on video, and with time-lapse of the magic he produces with his mouse. His 1969 Chevrolet Nova SS / AMERICAN MUSCLE rendition was an inspiration for the build, and while not an exact representation, the car JBA built was a working, realistic version that allowed for wheel / tire clearances as well as full turning radius. His work can be view on YouTube. Website: www.artstation.com/prokop_designer

Front end build sequence on widebody 1968 Chevrolet Nova

Digital Art

Artist Rostislav Prokop has the ability to take the images of a stock vehicle and with the magic of his keyboard, quickly create a “digital” rolling masterpiece, while he has a great talent for dreaming up creative body modifications, it’s a whole other thing to actually create it all on the 1:1 car…that’s where the talent of JBA Speed Shop comes it.

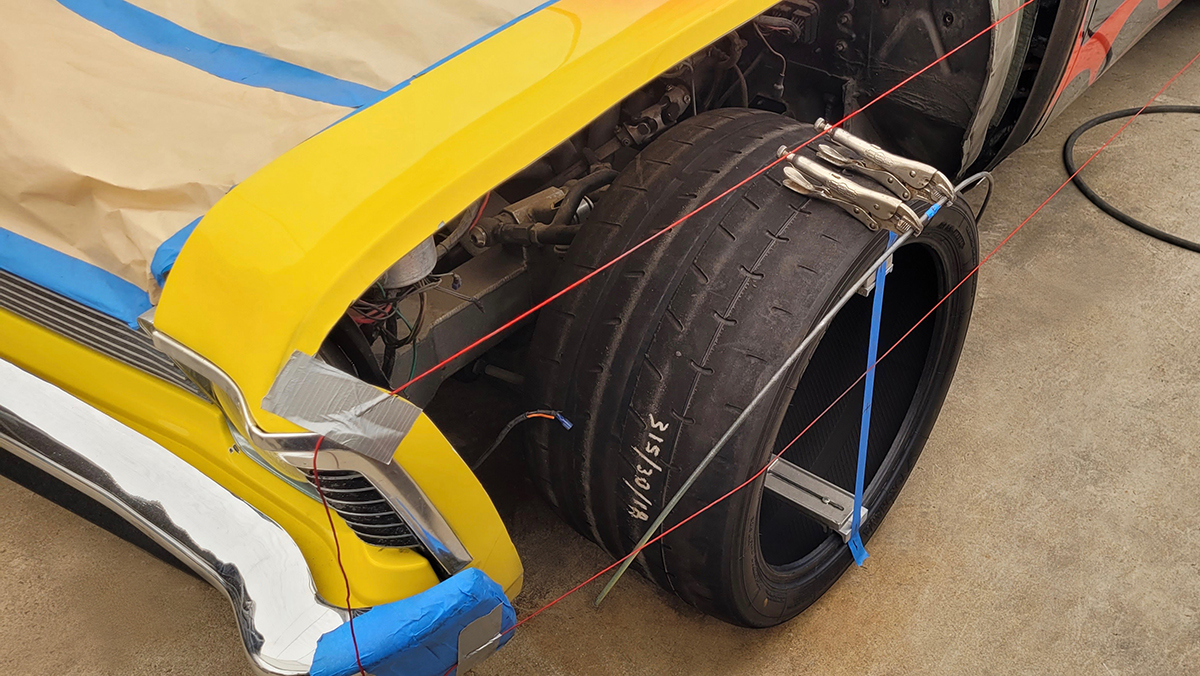

This early shot of the front fender shows the removal of the entire side sheet metal, but only after the factory sculpting angles had been verified (with reference templates made from small aluminum sheets). The wheel opening arch had been determined with the use of a length of 1/4″ wire rod in the desired location. In substitution of having the actual wheels (which had to special ordered) the tires were placed in a wheel offset gauge devise (normally used in determining correct offsets).

Ya gotta’ start somewhere! Red String and a bit of duct tape was the early beginnings of the new front fenders…all the while planning on the new, metal sculpturing to properly provide the needed tire clearance for street driving (driveways, bumps, lock to lock steering).

The art of positioning the wire rod in the desired locations is something that comes with experience, plus the important fact that the passenger’s side and driver’s side must be an exact match!

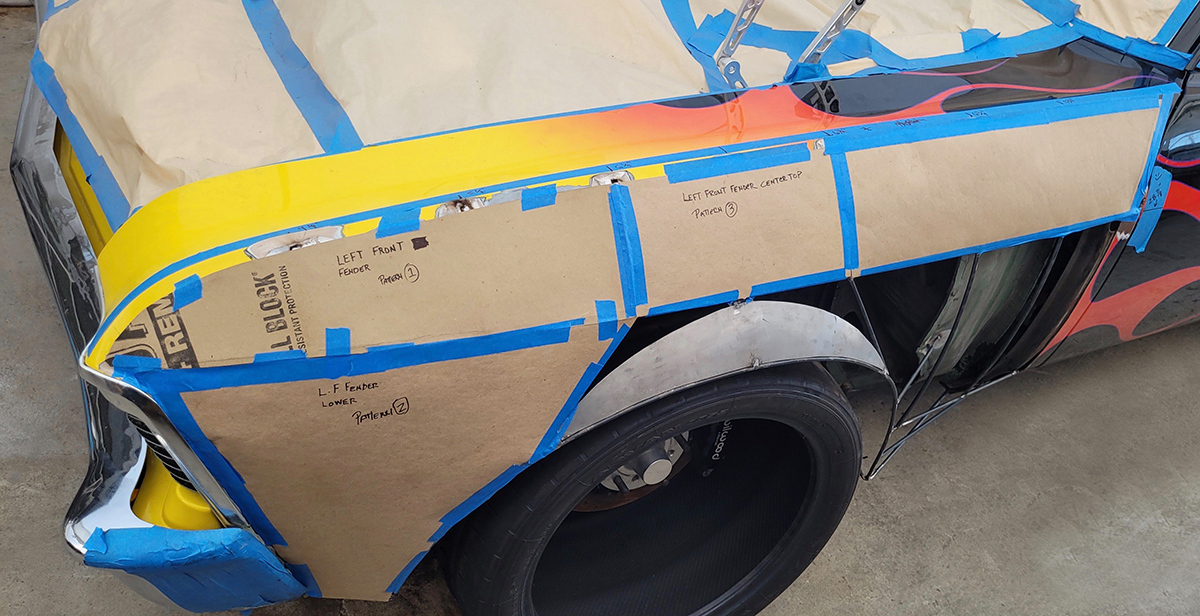

Construction paper was the first step in previewing how the metal panels are to be designed, and when the 18-gauge sheet metal individual panels are fitted they are referred to as “stations,” and created with an old-time English wheel.

Moving on to metalwork

After precision shaping and fitting of the stations they are butted-in to one another, seamed together with lead, 30-percent tin, 70-percent lead. This is all about metal finishing and no plastic filler.

Low-heat and small welding together of the panels insure no warping and each operation is done with special care to minimize the need for hammer and dolly finish work.

The new front fenders are starting to take shape!

After the metal finishing work was completed, a “guide coat” black lacquer went over the primer and when blocking it with sandpaper, the high spots and low spots are revealed.

When the time came to design and build new inner fenders on the rear a page out of the ancient times of Japanese “Origami” came into play. The process is all about paper folding to create shapes such as a paper crane, and in this case, precision-cut cardboard to be transformed into 18-gauge sheet metal for design of the enlarged inner fenders.

All new inner fenders were designed and built to deal with the massive tire and wheel assembly, and the outsides were finished in an OE manner just like the way Chevrolet did them on production cars…only these are now much wider.

Building the rear of the widebody Chevrolet Nova

Same as the front, the Internet artist was able to quickly whip up new quarter-panel designs to deal with the widening and enlarging to cover the big rollers…but the team at JBA had to actually make it happen for real.

At this stage it was time to get a little sampling of what the end product was to look like — time to get some cardboard and some black spray paint, it was a way for the crew to see “the light at the end of the tunnel” and they were pleased with the preview that was created.

A project of this nature is truly a step-by-step process, and these images are a glimpse of the extreme detail work involved.

A sequence of “in process” shots detailing the metal working involved, the leading of the stations together after precise fitting, the work was done with expertise. No Bondo!

This nearly “ready for paint” shot shows the standard smooth door skins, of which soon were to be modified with a peak-line that would match the lines that were incorporated into the front fenders and rear quarter panels.

The fabrication of the wire frame serves as a “backbone” to the new sheetmetal, and this view was covered by upholstered trunk side panels.

The artwork done up by Rostislav Prokop provided inspiration however in certain instances there were changes done by the JBA team, as example the design of the rear quarter panels had the tire tread much more covered by the sheetmetal, as well as a generally smoother appearance.

1968 Widebody Chevrolet Nova Build Images

Exterior Shots

With the “restyling” of the car, this 1968 Chevy Nova definitely now has a unique one-of-a-kind appearance, a wider stance and an aggressive look, all done to provide expanded wheel and tire clearance. Black paint and blacked-out everything certainly gives it a certain sinister appearance.

The rearview beauty shows the semi-fastback rood design from GM, and the bulged-out rear quarter panels from JBA Speed Shop! The goal was to enclose the extra-wide rubber all the while maintaining an aesthetic appeal.

When the preliminary fabrication work was being done on the new quarter-panels the decision was made to add some “air extractors” to the design, it was a way to create some detail work by adding a character styling element. There was an attempt to add another similar opening to the front of the rear wheel opening as well, it was “too busy” looking as sometimes the old adage applies: “enough is enough.”

20-inch diameter 2-piece, 10-spoke forged “Grand Prix Concave” Wheels from US Mag were chosen, featuring billet 6061 T-6 material and Mat Black centers. Front wheels measure 11-inches in width, wrapped with Michelin 305/30/ZR-20 Pilot Sport Cup 2 rubber. 12-inch wide wheels on the rear, with sized 335/30/ZR20-20 matching tread pattern Michelin rubber.

Rear-view vantage point highlights the distinctive side sculpturing, all done in steel and mission accomplished in covering the large, wide rolling stock!

Blacked-out grille and bumper, flared-out side, fat rubber, it’s got a look all its own after the crew at JBA was done.

The 1969 Camaro had an available “Cowl Induction” hood as optional, a 2-inch increase of height from stock. A fiberglass Nova hood with the Camaro-sourced “Super Scoop” was added to the car, and opening was made for the induction system…trimmed precisely to fit.

Interior, engine bay, and running gear

Big block fits snugly into the Nova’s engine compartment, and slightly overflows on the top with the supercharger intake and plumbing! Vortech Supercharger provides the power boost — 605 horsepower at 6200 rpm as verified on the dynomometer, set at 6-pounds of boost, Torque rated at 540 pds-ft at 5800 rpm. Aluminum radiator keeps it cool and the batter was moved to the trunk as it was already a crowded space.

3-spoke leather-wrapped wheel, full assortment of Autometer instruments and B&M Mega auto shifter highlights the interior.

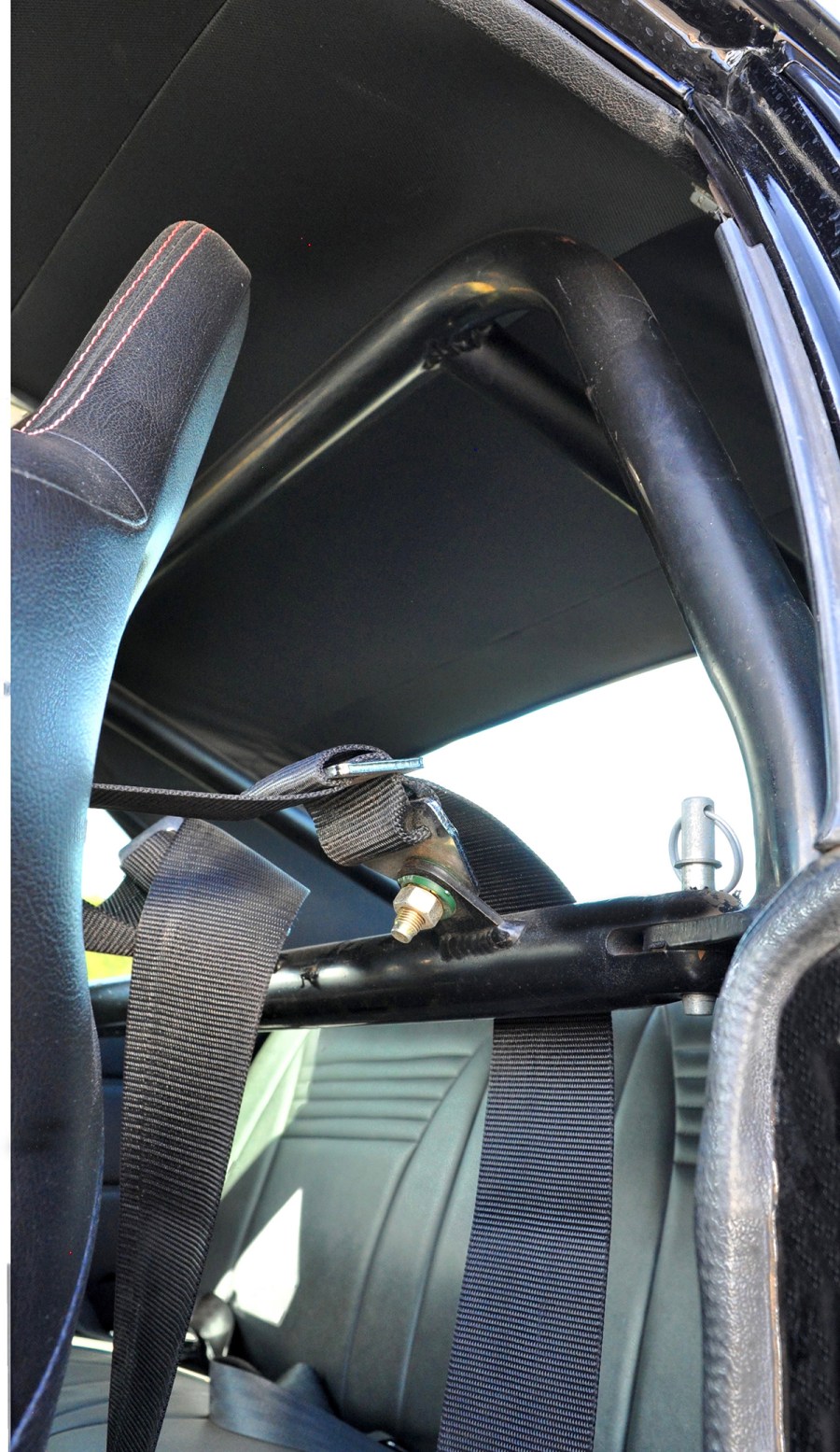

Seating provided with a pair of Corbeau Racing Seat buckets, complete with 4-point harness belts.

Trunk compartment detailed out in show car quality, Pioneer sound system (subwoofer shown) provides the audio, what can be heard over and above that throaty 454 big block!

Safety enhancements comes from Autopower 4-point roll bar, with swing-out center bar for back seat access.

To deal with the increased torque and horsepower, a “Fab9” rear axle was fitted, incorporating the Ford 9-inch center section with fabricated (for increased strength) housing. Rear sway and adjustable coil-overs did lots for improved handling abilities!

Up front there’s an aftermarket subframe, rack-and-pinion steering upgrade, tubular A-arms and Wilwood disc brakes.