It’s a common term in car tuning, but what does a wastegate actually do? Well, you’re about to find out with the Fast Car wastegate guide.

The wastegate’s sole job is to regulate boost pressure. It does this by letting exhaust gases out of the engine by bypassing the turbocharger rather than travelling through it. This prevents the turbo from spinning too fast, which in turn keeps the boost at the desired level. You generally need one wastegate per turbo, but running two is sometimes needed. Wastegates also come in various sizes depending how much flow the engine needs, and how much room there is to fit them.

How does a wastegate operate?

It’s quite a simple device that mounts on the exhaust manifold before the turbocharger, and is basically a spring-operated valve. Your car’s boost pressure acts against a diaphragm to push against the spring and therefore open the wastegate. The process is slightly different on internal and external wastegates, so read on and we will explain…

External wastegate is clearly visible to the right of the turbo

Can I fit a wastegate to my car?

Well to start with, if you have a petrol turbo car, you will almost certainly already have a wastegate, and if you don’t have a turbo, then you don’t need one! Aside from a few very rare exceptions, production turbo cars come with an internal wastegate attached to the turbo, so to fit an external one you will need an aftermarket exhaust manifold with an external wastegate outlet on it. For many popular turbo cars, especially Japanese ones, these are widely available. But if that’s not the case with your car, you’ll need to fabricate a custom exhaust manifold to suit your choice of wastegate.

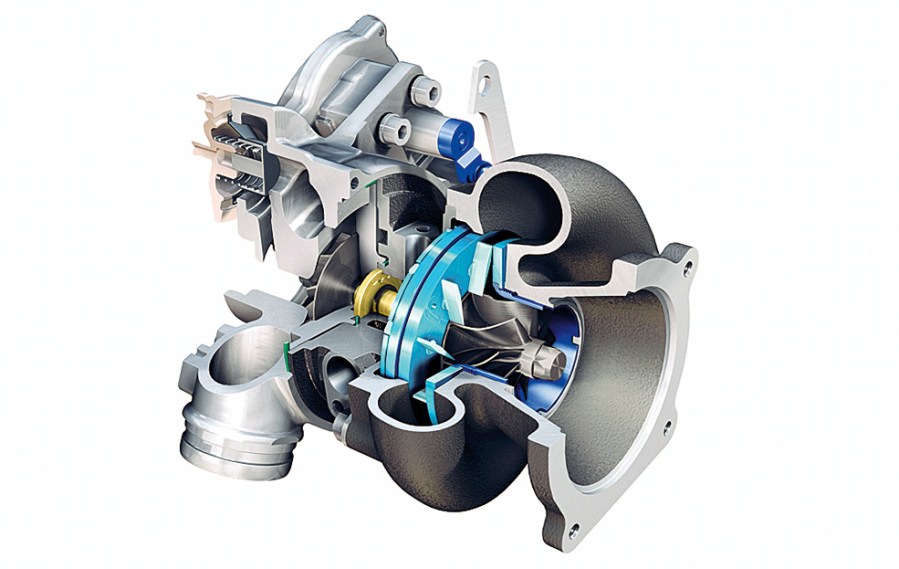

This cutaway shows a turbo with an internal wastegate attached

Do all engines have a wastegate?

Only turbocharged engines have a wastegate, but some of them don’t, and this is for two main reasons.

The most common reason is where the engine is running a variable geometry turbocharger (VGT), which instead of regulating boost with a wastegate, has sliding vanes in the turbine housing which effectively increase the turbine size to prevent the turbo overspeeding. Although on some engines, a VGT turbo also has a wastegate as a secondary control measure.

The second reason is seldom seen these days. This would be if the turbo was either so big, or so restricted (inlet and exhaust restrictions usually), that the turbo spools so slowly it cannot exceed maximum safe boost before the rev limiter. As you can imagine, this makes for a pretty horrible car to drive, with either huge lag, slow response, low rev limit, or a combination of all of these. Not good.

What size wastegate do I need?

Sizing is a common question with two answers, one of which is very complex and one that is far easier to understand. In layman’s terms, if your wastegate is too small it will not flow enough air, making your boost levels higher than desired. In theory, if it’s too big it may struggle to accurately keep the boost pressure stable. On the whole, the bigger your turbo is in comparison to your engine size, and the lower boost you want to run, the bigger the wastegate needs to be.

The more complex answer would involve some heavy math to calculate the minimum size wastegate that would still flow enough air for the given application. But in reality, even large wastegates rarely suffer from boost instability. Our advice is to run as big as you can fit, as if you end up with a wastegate that’s too small, the consequences are far worse!

Internal or External Wastegate?

On some cars you have no option as the turbo will either come with an external or internal wastegate. They work in slightly different ways, and there are pros and cons to both.

An external ‘gate is separate from the turbo and much larger in size

External Wastegates

Running an external wastegate costs a little more, and takes up more room (some are as big as a can of lager), but have many advantages. The main advantage is flow, as they can be over three times the size of an internal wastegate. This is important when you need to run a big turbo at low boost, and can also help performance by improving exhaust flow; especially if you vent it into a separate exhaust pipe.

The function is similar to an internal one, but rather than a hinged flap to vent the air, it uses a conventional spring-operated valve. There’s a diaphragm under the spring in a sealed housing, and boost pressure underneath this diaphragm pushes the diaphragm up, along with the spring, and therefore lifts the valve off its seat. This opens the wastegate and vents the excess boost pressure away.

Internal wastegate has an integral ‘flap’ that vents excess boost.

Internal Wastegates

The advantage of internal wastegates is that manufacturers build them into the turbo, making them cheap and compact. However, they generally aren’t as big as external units, so can’t flow a huge amount of gas; sometimes simply not enough to keep the turbo at low enough boost pressures for the engine in question.

On an internal one, the valve is a hinged flap built into the turbo exhaust housing, and is opened by a rod which is connected to a diaphragm inside a sealed container called the actuator. A spring inside the actuator holds the rod in the closed position and as the boost pressure rises it pushes on the diaphragm. This overcomes the spring pressure, and pushes the rod forwards, opening the wastegate.

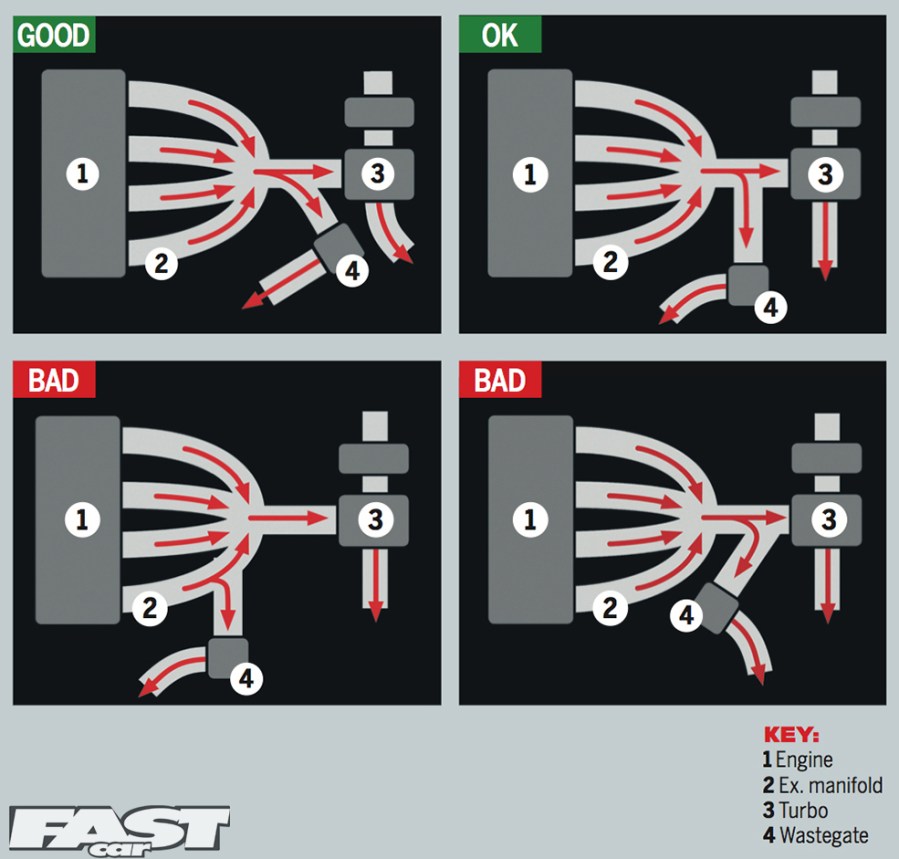

Positioning

As mentioned, the wastegate needs to be mounted on the exhaust manifold before the turbocharger, but the better the positioning of it, the better it will flow for any given wastegate size. The most important thing to consider is that a wastegate has to vent gas from all cylinders, which means you should ideally mount it on the collector, just before the turbo. Not all are like this, often out of necessity though, as doing otherwise significantly reduces flow and can lead to poor boost control and other issues.

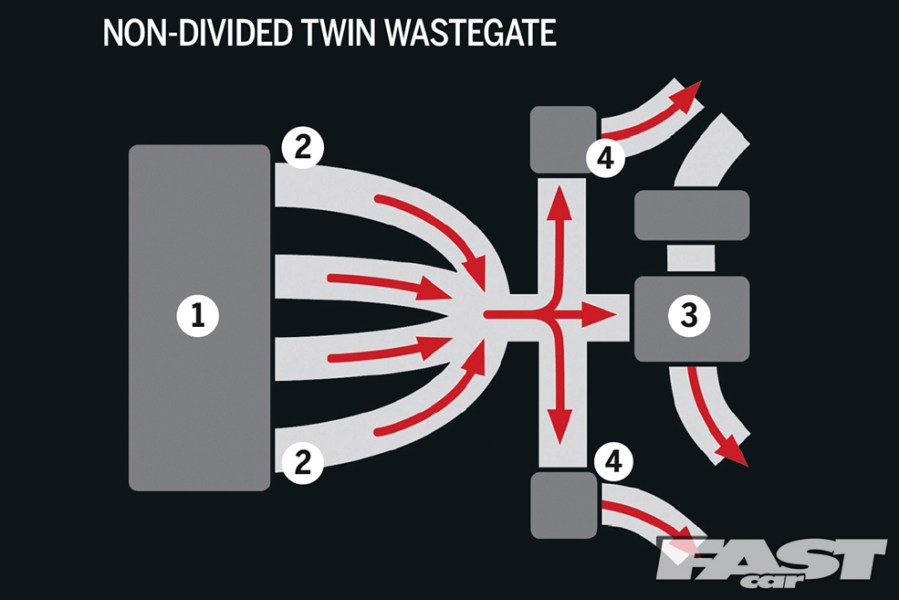

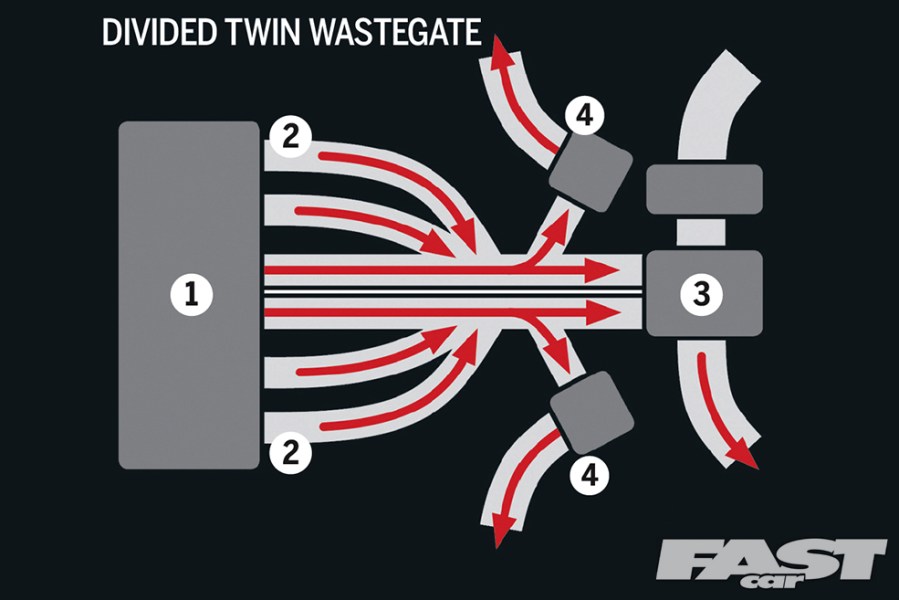

Secondly, the flow to the wastegate should be smooth, less than 45 degrees to the direction of the exhaust flow is ideal, but if this is not possible certainly no more than 90 degrees if you wish to have any boost control at all. The same principles apply in twin setups, as shown below.

Apex’i AVC-R is a popular boost controller

How do you control when a wastegate opens?

In its most basic form, the strength of the spring will dictate at what boost the wastegate opens, as the stronger the spring the more boost pressure it will take to open it. You can adjust this simply by changing the spring to a stronger one.

The other way to control the boost level is with one of the many electronic or mechanical boost controllers on the market. These items don’t allow you to set the boost lower than the spring allows, but can fool the wastegate into opening later by stopping some, or all of the boost pushing against the spring.

As a general rule your spring pressure should be at least half what your maximum boost pressure is, and your maximum should be set with the controller. But, it is possible to run wastegate spring pressure alone or run far more than double the wastegate spring pressure by using a controller.

Twin Wastegates

You sometimes, even on standard vehicles in rare occasions, have two wastegates per turbo, and the reasons for this are twofold. The simplest explanation is if, for whatever reason, you cannot fit a single that’s big enough to bypass enough exhaust gas, this can either be for space considerations or simply because you are running an enormous turbo at relatively low boost.

The more complex but common reason is because you are running a divided turbo setup. Divided turbo setups theoretically give you better overall performance, but to be fully divided you need one for each side of the divide, and late-spec FC RX-7 Turbos even came with a turbo that had twin internal wastegates as standard, although we have never seen an aftermarket turbo with twin internal wastegates before.

This big-power R34 has screamer pipes in its sideskirts.

Screamer Pipes & Wastegate Outlets

Another advantage with an external wastegate is that you can run a separate exhaust pipe from it, usually called a screamer pipe due to the noise it makes at full boost if unsilenced. Running a separate pipe from the wastegate means less restriction in the main exhaust, potentially giving more power, but also making the car incredibly noisy at full boost, though it doesn’t emit noise when the wastegate is shut.

Because of this people usually just plumb the external wastegate outlet back in to the exhaust system, but that can be restrictive unless you have a very large exhaust, so the ideal solution is a separate pipe from the wastegate, but with a silencer on it too – effectively a screamer pipe that doesn’t scream. On an internal wastegate the outlet is just as important for good flow, and many standard cars have a very restrictive outlet which means a redesigned and larger turbo elbow or downpipe gives good gains and better boost control.

There are internal screamer pipes on the market, but these really aren’t recommended. They rarely fully seal off the wastegate which means your car sounds like it has an exhaust leak at all times, and I don’t think we need to tell you how rubbish that sounds.

‘chatter’ is actually air venting back through the turbo blades.

Wastegate Chatter

There is a common myth in the performance tuning scene. It’s what most people call ‘wastegate chatter’ – the fluttering noise that happens when you lift off the throttle on some turbo cars. In reality that noise has nothing to do with the wastegate, and is in fact the air compressed by the turbo escaping back through it after having hit the closed throttle butterfly and having no other means of escape.

There is also a less common myth that certain types of dump valve make the chattering noise, but a dump valve will actually reduce this chattering as its job is to vent boost when the throttle is closed. However, different types of dump valve can give out a similar noise.