When tuning starts to get serious, no matter what you do with regard to induction kits, there will still be some kind of restriction elsewhere on the inlet side. Here’s our guide to stage 2 induction upgrades.

Your induction system includes every part of the car up to the cylinder head itself, and while we’re not going to talk about turbos and superchargers (as they’re subjects in their own right), your standard inlet manifold and throttle setup is all part of it. And these may be the parts holding your engine’s performance back.

Uprated throttle body

Standard throttle bodies are generally designed with standard power in mind and not a single horsepower more. So, increasing power and increasing throttle body diameter often goes hand in hand; particularly on naturally aspirated engines where the air isn’t being forced in by a turbo or supercharger.

With most production cars designed with cost, as much as performance, in mind, size isn’t the only problem. Often general flow is poor as the expense required to make super-smooth flowing parts outweighs the performance improvements in the eyes of most manufacturers.

As you’ve probably guessed, uprated throttle bodies tend to have larger diameter throttle plates and a smoother flow than the factory versions. Larger diameter throttle plates allow much more airflow than standard, but you have to be careful not to fit an overly large unit, as going too big will just reduce throttle control; sometimes meaning no more power is gained from about three-quarter throttle, to full throttle. A smooth flowing throttle body is an easily forgotten upgrade as it’s not visible when fitted. But reducing any steps, bumps, or sudden changes in size within the throttle body can make very noticeable improvements in performance, if the standard setup is a poor design.

Performance inlet manifold

Factory inlet manifolds are usually made with maximum drivability at the standard power figure in mind, rather than for power increasing modifications. So, on many engines, they seem to have been designed as an afterthought with little performance consideration at all. Because of this, on certain engines, aftermarket inlet manifolds can give great gains.

While the long, thin, inlet runners and tiny plenum of a standard inlet may give the best throttle response and low down torque, on most engines, it’s usually at the expense of high-rpm performance. A larger, freer-flowing inlet manifold can, potentially, give a big performance increase, especially when combined with other engine mods, such as uprated camshafts.

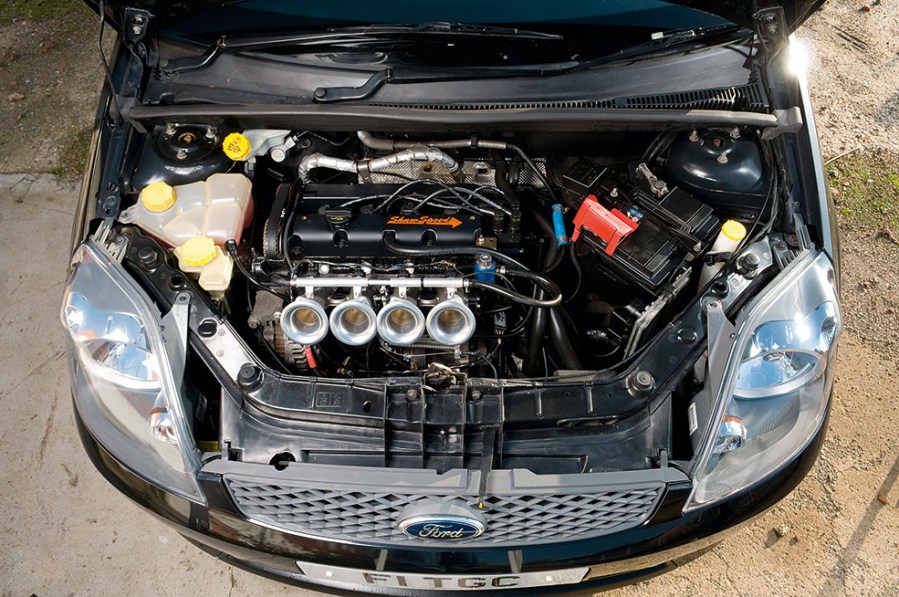

Individual throttle bodies

This is the ultimate induction setup, and the vast majority of race cars, as well as many highly-tuned road cars, utilise this design. Individual throttle bodies, often known as ITBs, are exactly as they sound like. They replace the standard single throttle with one throttle for each of the engine’s cylinders. Having one throttle per cylinder not only tends to give the highest airflow and least restriction, but it allows the throttles to be placed really close to the inlet valves, giving the engine lightning throttle response.

Another advantage of ITBs is they allow an engine to run wild cams while retaining drivability, as big cams often struggle to run well with a single throttle inlet design. An ITB conversion may be the ultimate in performance induction setups, but it’s not cheap or easy. Not only do you need to buy the ITBs themselves, but they require aftermarket engine management, an inlet manifold to bolt them to, a new air filter setup, not to mention loads of other bits and pieces.

While it’s not a performance consideration, the final bonus of running ITBs is a big draw for many, and that’s the fact that not only do they give a huge induction roar, but they transform an engine bay – every engine looks awesome with ITBs fitted. Fact.

Carb conversion

Swapping factory fuel injection for carbs is rare these days. Modern emissions laws mean it’s hard to get a carb equipped car to pass an MoT, and ITBs (which give similar maximum performance but much better drivability), are far less expensive than they used to be. But carbs are still a viable option if you want them; especially on an older car.

For most inline four or six-cylinder engines, a twin or triple-carb conversion looks just like an ITB setup, and gives similar peak performance gains too. Many V8s simply run one giant carb in the centre of the Vee, which gives a big performance increase, without the expense of fitting eight separate throttles for an ITB setup. This eliminates the need to fit aftermarket engine management.

Induction system considerations

We talked about all the different kinds of induction system in our Fast Car Induction Kit Guide, there’s a variety of options with each type, and although they often look simple, the reality is far from it. Big-budget race cars have insane amounts of time and money spent testing and designing their inlet components, and while few of us have that kind of money, actually thinking about your induction system design, rather than just slapping on the first filter you see can give you worthwhile gains.

Filter size

You can have the fanciest induction setup on the planet, but it’s only as good as its biggest restriction, so if your air filter is too small, you’re simply not going to produce the power you want. Underestimating the filter size needed is a common problem on turbo and supercharged cars, but it happens on tuned N/A motors too, and enough air is far more important than cold air. So if you do nothing else, make sure your air filter is actually big enough!

Air box size

Just like filter size, if an airbox can’t actually flow the amount of air your engine needs, it can’t make maximum power, no matter how cool the air is. An overly small performance airbox is a common mistake, especially on big-power turbo cars, as fitting an airbox designed for a 300bhp rally car for example will just restrict a 600bhp engine. It’s no surprise big-power drag and rallycross engines often run an open filter; there’s simply no room for an air box big enough for the power level they are running.

Inlet temperature

As already mentioned, getting enough air is more important than having cold air, but as long as you have adequate airflow, the key to maximum performance is colder air. The cooler the air is, the denser it is, which means more oxygen content for any given amount of air. Combine that with the corresponding amount of fuel and you get more power, simple really.

Velocity stacks

Velocity stacks are the cool looking alloy trumpets fitted to many induction systems, often before an airbox or on the outlet of a cone filter. They are actually mounted inside some top quality inlet manifolds; these things actually have a bigger effect on performance than people realise. The main reason is they smooth the flow into the inlet, reducing turbulence, which in turn increases flow and therefore power potential. The second reason, especially on setups where it’s at the beginning of the induction system, is the large trumpet shape inlet means it’s hitting a larger cross section of airflow than a small diameter pipe. The final reason is to do with something called the Bernoulli Principle, and it basically means airflow travelling through a pipe that smoothly tapers inwards, should speed up as the diameter decreases, which potentially means more airflow is forced in than a pipe that stays the same diameter from the beginning.

Induction pipe diameter

In theory, a smaller pipe should increase gas speed, which may have performance advantages. But, in reality (pre-throttle at least) it’s more likely to cause a flow restriction. It’s easy to think that because your throttle body is only 50mm you only need a 50mm induction pipe, but this is rarely true. So, provided you can fit one, a large-bore induction pipe is usually best for performance; though as with most induction changes, don’t expect magical huge gains just by fitting a giant drainpipe intake.

Heat shielding

As already mentioned, high inlet temps are the enemy to making power, so anything you can do to avoid it, without creating a flow restriction is a good thing. The main heat in your engine bay comes from the exhaust. So fitting a heat shield around the air filter or exhaust manifold, and ideally preventing heat from escaping the exhaust by using heat wrap or ceramic coating, is always a good thing; especially if your induction system runs near the exhaust.

As all engine components get hot, another effective thing is to prevent the induction pipework from soaking up any of this heat. This can be done not only by keeping it away from any hot parts, but by wrapping it in head reflec- tive materials. Self-adhesive heat wrap is surprisingly cheap to buy and a look in many race car engine bays will reveal they are covered in the stuff; heat management is a really effective but under-used area of tuning.

Pipe length

The longer a pipe is, the more restrictive it is for any given diameter. So while creating a hugely long inlet pipe that sucks cold air from low in your front bumper sounds like a great idea, unless you make it a suitably large diameter, it may be quite restrictive and a much less impressive performer than your might imagine.

Pipe shape

Bends – tight bends especially – are a restriction, so if a straight inlet isn’t possible, make sure you use smooth, large radius bends, and also compensate for the bends by having large diameter pipework. Certain induction pipework exists which is specially shaped with improved performance in mind. This includes creating a large plenum area just before the throttle body (like Japanese tuner ARC often do) to allow engines to take a bigger gulp of air under sudden throttle openings. There’s also the common ‘Whale Penis’ intakes available for many Hondas, which take the large induction pipe theory even further, by gently tapering in the closer it gets to the throttle body, using the Bernoulli Principle mentioned earlier, to attempt to increase performance.

Air flow meters (AFM/MAF)

Most modern cars have air flow meters or MAF sensors fitted in the induction system, usually located just after the standard airbox. Without reprogramming or replacing the standard ECU, these can’t be enlarged or removed, so depending on the engine and its state of tune, these may actually be the most restrictive part of your inlet system.

Most newer models come with relatively free-flowing MAF sensors, but on many cars from the 1990s and earlier, the airflow meter is quite a restriction. Unfortunately they are vital sensors for your car’s engine management system, so without swapping to AFM/MAF-less engine management, there’s very little you can do.

The final thing to take note of is, some of these sensors are incredibly sensitive to contamination, from dust and dirt to even the filtration oil used with some aftermarket filters. These things can very easily damage certain MAF sensors, making your engine run like crap and potentially seriously denting your wallet to replace.

Running with no air filter

We’ve all seen drag cars and big power Japanese imports running with no air filter at all, but unless you’re on the drag strip this really isn’t a good idea at all. The reason it’s done on huge power drag cars is valid; there’s simply no filter big enough that will fit that won’t cause a restriction to power, but with K&N for example making cone filters proven at well over 1000bhp, and with all the dust, dirt, stones, insects, and small children just waiting to get sucked in to your engine and smash it to pieces, you’d be crazy not to run a filter on the road.

Filter socks

If you’ve fitted a set of ITBs or carbs, the obvious solution to how the hell you are going to fit an air filter to your new induction setup is to simply fit foam filter socks over the end of your induction trumpets; they’re small, cheap, and easy to fit, and as loads of people run them they must be good, right? Wrong.

To put it simply, they’re pretty rubbish compared to a proper air filter. A foam filter over the end of your inlet trumpet means an incredibly small filter surface area, a huge restriction on most engines, which not only massively restricts power, but it’s quite common for the vacuum caused by the restriction to actually suck the trumpet in to the engine, and a whole foam filter being swallowed by your engine will do a lot more damage than the dirt it was attempting to filter would!

Words Stav Photos Various